ATLEHISA Case

Project sebaka: Jeremane

Project nako: 2012

Customer o ka sehloohong dihlahiswa: qetela methaka Rubber (bakeng sa litiiso rabara), e mong oa kholo ka ho fetisisa bahlahisi phala tiiso Europe

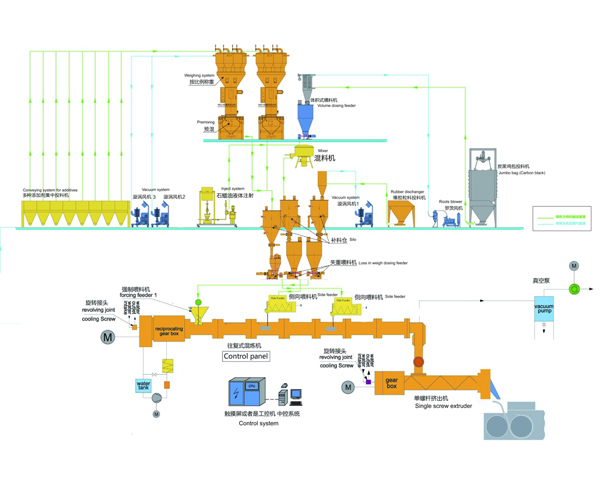

XINDA mochini: 3-sefofane Co-kneader SJW-200

Selelekela tsa morero

1. Ka 2011, moreki tšohloa tshebetso e ncha tlhahiso ea lihlahisoa tsa bona le XINDA, 'me ka bobeli fumana ho sebelisana ka R & D. Nakong ena, ba ile ba fetola tshebetso tlhahiso ea ka Xinda laboratori ea ho ka makhetlo a mangata' me a nka e khutlela Jeremane bakeng sa liteko tse ka makhetlo-khetlo. Ho qetela boleng sehlahisoa feta pele.

2.In 2012, the customer purchased xinda co-kneader SJW-200 to produce final batch rubber for rubber seal products, changing the processing technology of traditional banbury kneaders and milling rollers, which greatly improved the stability of product performance. At the same time, high degree of automation of Co-kneader improved the workshop production environment. The capacity per unit compounding line can reach 10,000 tons/year.

Moreki o Feedback le Review

1. Low beola le phahameng hasana ke bath ea khethehileng oa Co-kneader. lihlahisoa tse tala, joaloka likaroloana rabara, carbon ntšo, oli e tšoeu, rabara accelerant le ho phekola moemeli joalo joalo, kena le eena ka reciprocating mochini dikarolong, le nepahetse taolo tse bonahalang mocheso, hasana lekaneng le ho kopanya, tshebetso babatsehang sehlahiswa le e ntle sehlahiswa pathomorphology le botsitso.

2. tekanyo ea ho seba ba Co-kneader tlhahiso ke haholo e phahameng. lihlahisoa tse tala e ka arotsoe ka lihlopha le metered ka likarolo ka oona tsamaisong fepa gravimetric. The likaroloana rabara, carbon ntšo, oli e tšoeu, 'me moemeli vulcanizing di fepa ka tsela e koetsoeng. Kahoo tikoloho kokoano tlhahiso ea e hloekile haholo.

3.Three-sefofane Co-kneader SJW-200 e na le e phahameng bokgoni tlhahiso le tshebediso ya tlaase matla. Ha ho bapisoa le ho hloekisoa ea setso hare mmoho bulehileng hloekisoa thepa tlhahiso, sa tshebediso ya eneji, ka ton e fokotsehile ka 20% - 30%.

4. holimo-sethaleng reciprocating mochini o inkela ka moralo khetla moqomo, ha nsete ea bobeli-sethaleng pelletizing extruder ka arohantsoe ke hula khutlela. Ka hona, ha mekhoa fetola kapa mochine hloka tokiso, ho ka potlako o ile a bula le ho hloekisa, e leng ka nako e khutsoaane nako ya ho sokoloha le tlhokomelo.