CASE GUUL

Goobta Project: Germany

Project time: 2012

waxyaabaha ugu muhiimsan ee Macmiilka ee: Dufcaddii Final Rabadhka, (waayo, shaabadood caag), mid ka mid ah soo saarayaasha seal biibiile ugu weyn ee Europe

mashiinka XINDA: 3-duulimaadka Co-kneader SJW-200

Hordhac mashruuca

1. In 2011, macaamiisha wada hadleen habka wax soo saarka cusub ee wax soo saarka ay la leeyihiin XINDA, iyo labada dhinac loo ogaado in ay iskaashi ee R & D. Muddadan, waxay beddelo habka wax soo saarka ee shaybaarka Xinda waayo, marar badan oo dib u qaaday in Germany baaritaanka soo noqnoqda. Tayada wax soo saarka final dhaafto asalka ah.

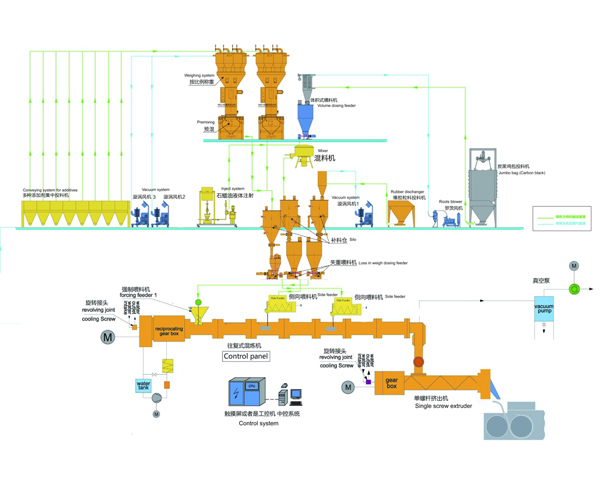

2.In 2012, the customer purchased xinda co-kneader SJW-200 to produce final batch rubber for rubber seal products, changing the processing technology of traditional banbury kneaders and milling rollers, which greatly improved the stability of product performance. At the same time, high degree of automation of Co-kneader improved the workshop production environment. The capacity per unit compounding line can reach 10,000 tons/year.

Jawaab-celinta Customer iyo Review

1. xiirid Low oo kala firidhsan sare waa dabeecadda gaarka ah ee Co-kneader. alaabta ceeriin, sida Qurub caag, madow carbon, saliid cad, accelerant caag iyo wakiilka daaweynta iyo wixii la mid ah, galaan oo iyana on mashiinka reciprocating ee qeybaha, iyadoo ay gacanta ku sax ah wax heerkulka, kala firidhsan ku filan iyo isku qasin, qaab wax soo saarka aad u fiican oo homogeneity sheyga wanaagsan iyo xasiloonida.

2. Degree of qalabaynta of Co-kneader ee wax soo saarka waa mid aad u sarreeya. alaabta ceeriin loo qaybin karaa kooxo iyo ayaa mitir qaybo loo sii marayo Nidaamka quudinta gravimetric. qayb ka ah caag, madow carbon, saliid cad, iyo wakiilka vulcanizing lagu quudiyo hab u xiran yihiin. Sidaas deegaanka soo saarka isweydaarsiga waa wax nadiif ah.

3.Three horyaalka Co-kneader SJW-200 uu leeyahay awood wax soo saarka sare iyo isticmaalka tamarta yar. Marka la barbar dhigo turxaan dhaqan gudaha lagu daray qalabka wax soo saarka turxaan furan, isticmaalka tamarta halkii ton laga dhimayaa 20% - 30%.

4. Mashiinka sare-yada reciprocating ansixiyeen design foosto clamshell ah, halka fur oo ka mid ah-yada labaad pelletizing extruder la kala saari karaan by jiidaya dib. Sidaa darteed, marka qaaciidooyinka beddelo ama mishiinka u baahan yahay dayactir, waxa si dhakhso ah u furay karo iyo nadiifin, oo koobaya waqtiga diinta iyo dayactirka.