ATLEHISA Case

Project sebaka: Japane, China, Turkey, Mexico, Thailand, joalo-joalo

Project nako: 2003- 2019

Customer o ka sehloohong dihlahiswa: Thermosetting thepa kang bōpa dipolasetiki phenol, Bakelite phofo, lehoakhoa unsaturated le polasetiki tiisoa ha ho thepa

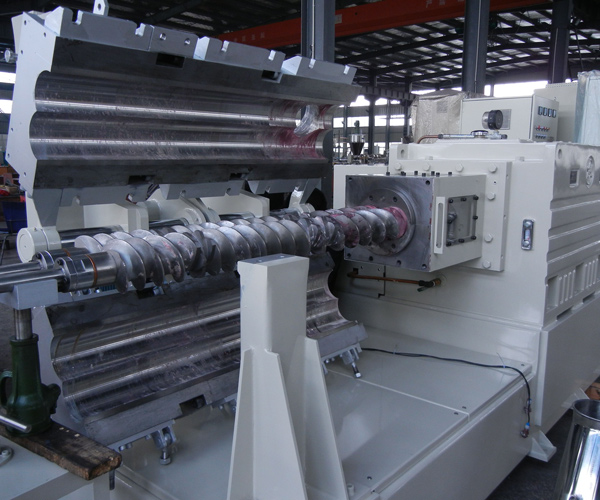

mochini XINDA: 3-sefofane Co-kneader le khetla moqomo Twin nsete Extruder

Selelekela tsa morero

gba 2003 ho de 2019, moreki e reka Co-kneader ho lihlahisoa thermosetting thepa kang metsoako phenol bōpa, e fetohile theknoloji e lokisa ya ea setso leloala bulehileng le haholo ba ntlafala botsitso ba tshebetso sehlahisoa. Ka nako e tšoanang, e phahameng tekanyo ea ho seba ba Co-kneader ntlafala tikoloho kokoano tlhahiso. Bokhoni ba ka joalo compounding mola ka fihla lithane tse 3,000-10,000 / selemo. Xinda fetohileng baabi le kholo ka ho fetisisa tsa thermosetting thepa thepa thepa ka China.

Moreki o Feedback le Review

1.With e ikhethang thekenoloji tsoaka la beola tlaase le phahameng hasana, mochine ka nepo a laola thempereichara lintho tse bonahalang tse, ka botlalo qhalakanye le kopanya, ka mocheso tlaase khohlano. E boetse e ka laola thempereichara theko le ho fumana mocheso ea tharollo ha se hlahisa phenol fetola metsoako mocheso-nahanela, eo ka nepo a ka laola mocheso lintho tse bonahalang. Ka mor'a ho arohana ka botlalo le ho kopanya, sehlahiswa o tshebetso babatsehang le pathomorphology ntle le botsitso.

2. The reciprocating and kneading machine(Co-kneader)and Clamshell Twin Screw Extruder has a high degree of automation in production. After the components such as phenolic resin, filler, auxiliary agent and cross-linking agent are premixed, the closed feeding mode makes the production environment of the workshop clean and the working environment of the workers greatly improved, which significantly reduces the labor intensity of the workers.

3. Three-sefofane reciprocating mochine kapa khetla mafahla nsete na tlhahiso phahameng le tshebediso ya tlaase matla, e leng se ka fokotsa tshebediso ya eneji, bapisoa le thepa ea setso bulehileng qhibilihisa tlhahiso.

4. The upper-stage reciprocating machine or twin screw extruder adopts a clamshell barrel design. When formulas change or the machine needs maintenance, it can be quickly opened and cleaned, which shortens the time of conversion and maintenance.