nasara GAME

Project wuri: Japan, China, Turkey, Mexico, Thailand, da dai sauransu

Project lokaci: 2003- 2019

Abokin ciniki ta babban kayayyakin: Thermosetting kayan kamar phenolic gyaren robobi, Bakelite foda, unsaturated guduro kuma roba sealing kayan

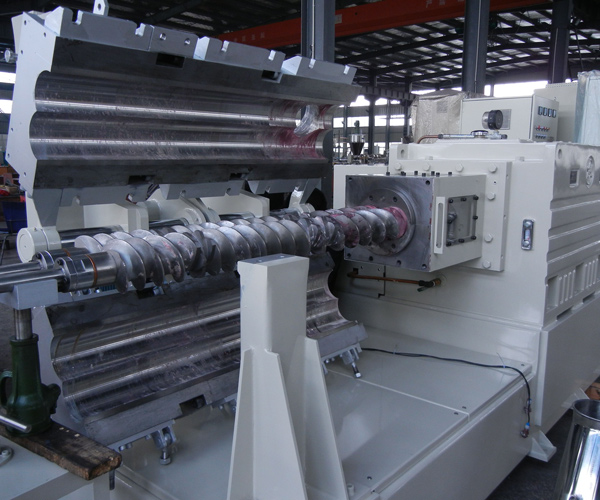

XINDA inji: 3-jirgin Co-kneader kuma Clamshell ganga Twin Dunƙule Extruder

Gabatarwa na aikin

Romawa 2003 zuwa 2019, a abokin ciniki sayi wani Co-kneader zuwa kayan thermosetting kayan kamar phenolic gyaren mahadi, wanda ya canja da aiki da fasaha na gargajiya bude niƙa kuma ƙwarai inganta zaman lafiyar na samfurin yi. A lokaci guda, babban mataki na aiki da na Co-kneader inganta bitar samar da yanayi. Da damar da irin compounding line iya isa 3,000-10,000 ton / shekara. Xinda ya zama mafi girma a maroki na thermosetting kayan Manufacturing kayan aiki a kasar Sin.

Abokin ciniki ta Feedback da kuma Review

1.With da musamman hadawa da fasaha na low karfi da kuma high watsawa, inji iya daidai sarrafa zafin jiki na kasa, da cikakken watsa da kuma Mix, tare da low gogayya zafi. Yana kuma iya sarrafa zafin jiki na shaft da kuma samu da yawan zafin jiki daga cikin bayani a lõkacin da ta samar da zafi-m phenolic gyaren mahadi, wanda zai iya daidai sarrafa kayan zazzabi. Bayan da cikakken watsawa da kuma hadawa, da samfurin yana da kyau kwarai yi da kyau homogeneity da kwanciyar hankali.

2. The reciprocating and kneading machine(Co-kneader)and Clamshell Twin Screw Extruder has a high degree of automation in production. After the components such as phenolic resin, filler, auxiliary agent and cross-linking agent are premixed, the closed feeding mode makes the production environment of the workshop clean and the working environment of the workers greatly improved, which significantly reduces the labor intensity of the workers.

3. Three-jirgin reciprocating inji ko Clamshell twin dunƙule yana da babban aiki da kuma low makamashi amfani, wanda zai iya rage makamashi amfani idan aka kwatanta da na gargajiya bude smelting samar da kayan aiki.

4. The upper-stage reciprocating machine or twin screw extruder adopts a clamshell barrel design. When formulas change or the machine needs maintenance, it can be quickly opened and cleaned, which shortens the time of conversion and maintenance.