CASE sukses

Lokasi Project: Jepang, China, Turkey, Mexico, Thailand, etc

Project wektu: 2003- 2019

produk utama pelanggan: Thermosetting bahan kayata plastik phenolic ngecor, wêdakakêna srengeng, resin unsaturated lan plastik bahan sealing

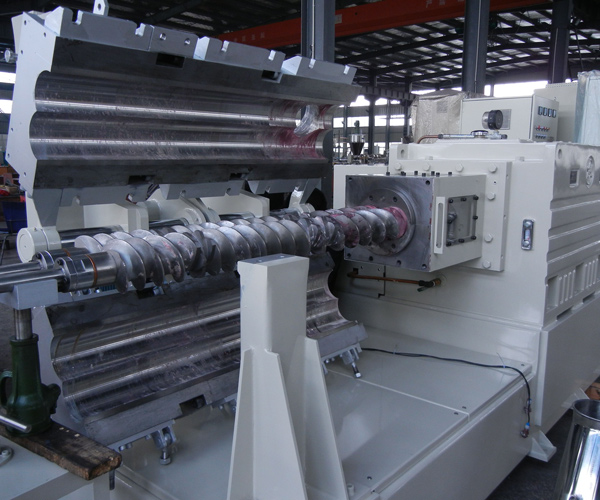

mesin XINDA: 3-pesawat Co-kneader lan clamshell tong minyak Twin Meneng Extruder

Pambuka proyèk

rom 2003 kanggo 2019, customer dituku Co-kneader kanggo gawé thermosetting bahan kayata senyawa ngecor phenolic, kang diganti teknologi Processing saka pabrik mbukak tradisional lan apik nemen stabilitas kinerja produk. Ing wektu sing padha, jurusan dhuwure automation saka Co-kneader apik lingkungan produksi bengkel. Kapasitas per baris compounding kuwi bisa tekan 3,000-10,000 ton / tahun. Xinda wis dadi Supplier paling gedhé thermosetting bahan peralatan Manufaktur ing China.

Komentar pelanggan lan Review

1.With teknologi nyawiji unik saka nyukur kurang lan sawur dhuwur, mesin kanthi bisa ngontrol suhu saka materi, kanthi mbubarake lan nyampur, karo panas kurang gesekan. Uga bisa ngontrol suhu batang lan diwenehi suhu ing solusi nalika mrodhuksi phenolic ngecor senyawa panas-sensitif, kang kanthi bisa ngontrol suhu materi. Sawise kebak sawur lan nyawiji, prodhuk wis banget kinerja lan homogeneity apik lan stabilitas.

2. The reciprocating and kneading machine(Co-kneader)and Clamshell Twin Screw Extruder has a high degree of automation in production. After the components such as phenolic resin, filler, auxiliary agent and cross-linking agent are premixed, the closed feeding mode makes the production environment of the workshop clean and the working environment of the workers greatly improved, which significantly reduces the labor intensity of the workers.

3. Three-pesawat mesin reciprocating utawa clamshell kembar meneng wis dhuwur produktivitas lan konsumsi energi kurang, kang bisa Ngartekno nyuda konsumsi energi dibandhingake karo tradisional alat produksine paleburan mbukak.

4. The upper-stage reciprocating machine or twin screw extruder adopts a clamshell barrel design. When formulas change or the machine needs maintenance, it can be quickly opened and cleaned, which shortens the time of conversion and maintenance.