ọma Ileba

Project ọnọdụ: Japan, China, Turkey, Mexico, Thailand, etc

Project oge: 2003- 2019

Ahịa isi ngwaahịa: Thermosetting ihe ndị dị ka phenolic ịkpụzi plastik, Bakelite ntụ ntụ, unsaturated resin na plastic akara ihe

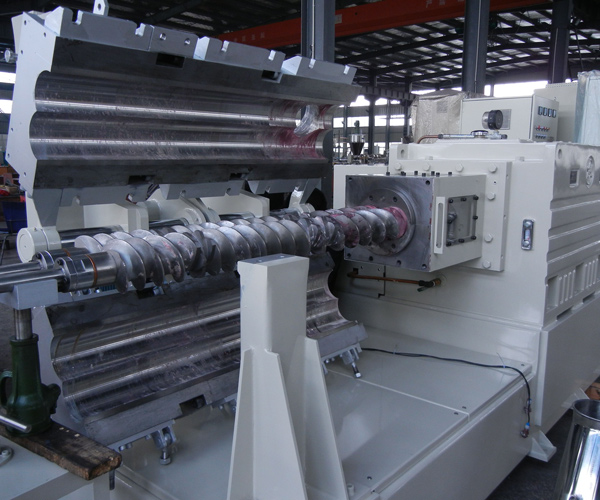

XINDA igwe: 3-elu Co-kneader na okpokoro akịrịkọ gbọmgbọm Ejima ịghasa Extruder

Okwu Mmalite nke oru ngo

rom 2003 2019, a ahịa zụrụ a Co-kneader ka mepụtara thermosetting ihe ndị dị ka phenolic ịkpụzi ogige, nke gbanwere nhazi technology nke omenala oghe na nkume igwe nri na ukwuu mma nke kwụsiri ike nke ngwaahịa arụmọrụ. N'otu oge ahụ, elu ogo akpaaka nke Co-kneader mma ogbako mmepụta gburugburu ebe obibi. The ikike kwa dika njọ akara nwere ike iru 3,000-10,000 tọn / afọ. Xinda aghọwo ndị kasị ibu soplaya thermosetting ihe n'ichepụta ngwá na China.

Ahịa si Nzaghachi na Review

1.With pụrụ iche Ịgwakọta technology nke ala shiee na elu dispersion, akụrụngwa ike n'ụzọ ziri ezi ịchịkwa okpomọkụ nke ihe onwunwe, n'ụzọ zuru ezu achụsakwa na mix, na ala esemokwu okpomọkụ. Ọ nwekwara ike ịchịkwa okpomọkụ nke aro na inweta okpomọkụ nke ihe ngwọta mgbe ọ na-arụpụta na okpomọkụ-enwe mmetụta ọsọ ọsọ phenolic n'ịkpụzi ogige, nke nwere ike n'ụzọ ziri ezi na-achịkwa ihe okpomọkụ. Mgbe n'ụzọ zuru ezu dispersion na agwakọta, ngwaahịa nwere magburu onwe arụmọrụ na ezi homogeneity ma kwụsie ike.

2. The reciprocating and kneading machine(Co-kneader)and Clamshell Twin Screw Extruder has a high degree of automation in production. After the components such as phenolic resin, filler, auxiliary agent and cross-linking agent are premixed, the closed feeding mode makes the production environment of the workshop clean and the working environment of the workers greatly improved, which significantly reduces the labor intensity of the workers.

3. Atọ-elu reciprocating igwe ma ọ bụ okpokoro akịrịkọ ejima ịghasa elu arụpụtaghị na ala oriri ike, nke nwere ike budata belata oriri ike tụnyere na omenala oghe n'oké mmepụta akụrụngwa.

4. The upper-stage reciprocating machine or twin screw extruder adopts a clamshell barrel design. When formulas change or the machine needs maintenance, it can be quickly opened and cleaned, which shortens the time of conversion and maintenance.