Successful CASE

Project lokaasje: Japan, Sina, Turkije, Mexico, Tailân, etc

Project tiid: 2003- 2019

Customer syn wichtichste produkten: Thermosetting materialen lykas phenolic moulding keunststoffen, Bakkelyt poeder, unsaturated hars en plastic sealing materiaal

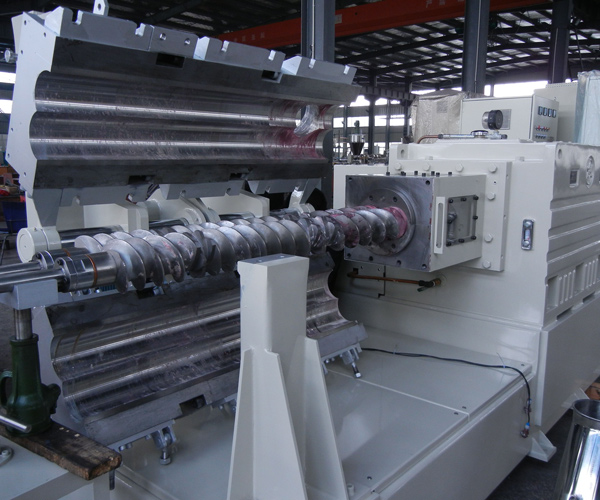

XINDA machine: 3-flight Co-kneader en Clamshell barrel Twin Screw Extruder

Yntroduksje fan it projekt

rom 2003 oant 2019, in klant kocht in Co-kneader te produsearjen thermosetting materialen lykas phenolic moulding ferbiningen, dy't feroare it ferwurkjen technology fan de tradisjonele iepen mûne en sterk ferbettere de stabiliteit fan it produkt foarstelling. Yn deselde tiid, hege mjitte fan automatisearring fan Co-kneader ferbettere de workshop produksjeklimaat. It fermogen per sa'n compounding rigel kin berikke 3,000-10,000 ton / it jier. Xinda is de grutste leveransier fan thermosetting materialen manufacturing ark yn Sina.

Klant Feedback en Review

1.With de unike mjuks technology fan lege Shear en hege dispersion, de masine kin sekuer behearskje de temperatuer fan it materiaal, folslein disperse en mix, mei lege wriuwing waarmte. It kin ek behearskje de temperatuer fan skacht en krije de temperatuer fan de oplossing as it produsearret waarmte-gefoelige phenolic moulding ferbiningen, dat kin sekuer behearskje it materiaal temperatuer. Nei folslein dispersion en it mingen, it produkt hat poerbêste prestaasje en goede homogeneity en stabiliteit.

2. The reciprocating and kneading machine(Co-kneader)and Clamshell Twin Screw Extruder has a high degree of automation in production. After the components such as phenolic resin, filler, auxiliary agent and cross-linking agent are premixed, the closed feeding mode makes the production environment of the workshop clean and the working environment of the workers greatly improved, which significantly reduces the labor intensity of the workers.

3. Three-flight reciprocating masine of Clamshell twilling skroef hat hege produktiviteit en lege enerzjy konsumpsje, dat kin gâns ferminderjen enerzjy ferbrûk yn ferliking mei tradisjoneel iepen smelting produksje apparatuer.

4. The upper-stage reciprocating machine or twin screw extruder adopts a clamshell barrel design. When formulas change or the machine needs maintenance, it can be quickly opened and cleaned, which shortens the time of conversion and maintenance.