-

Multi-werna PVC Flooring Senyawa Kneading Extruder System

LOW nyukur, LOW meksa, LOW TEMPERATURE Nanging HIGH kneading efficiency Kanggo kabutuhan Compounding YOUR -

Lab Micro Compounder Twin Meneng Extruder 35mm Pelletizing Kanggo Masterbatch Testing

Xinda wis kembar meneng extruder & co-kneader extruder kanggo aplikasi Lab, kang digunakake kanggo masterbatches, compounding pvc, ngisi masterbatches Testing, ECT -

High Concerntrated Color Masterbatches Compounding Making Machine With Four Flights Screw

Description For Products Application For Co-kneader Output For Reference Layout for HFFR working process Output For Reference Model SKW-85 SKW-105 SKW-125 Co-kneader Screw Diameter 85 105 125 L/D Ratio 15-22 15-22 15-22 Max.Motor Power 600 600 600 Main Motor Power 110-160 200-280 350-450 Second-stage Screw Diameter 150 180 220 Second-stage Screw L/D Ratio 7 7 7 Max.Screw Speed 60 60 60 Second-stage Motor Power 55 75 110 Reference Output(KG) SKW-85 SKW-105 SKW-125 ... -

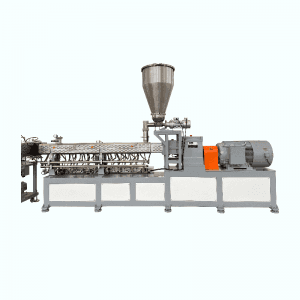

Concentrates Masterbatch Compounding Extruder And Pelletizing Line

XINDA Co-Kneader family SJW(M) System SJW(C) System SJW(T)System SJW(M) System Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Applic... -

Four Tiket Co-kneader Senyawa Extruder kanggo HFFR utawa XLPE

XINDA develops teknologi anyar karo 4 penerbangan. The XINDA SKW kneader saben spiral wis bejat dening papat kesenjangan saben revolusi nemokake penerbangan kneading kanggo. Patang larik kneading lencana, kang individu dipasang ing tong minyak saben 90 degree, sing intermeshed karo penerbangan iki. Kanthi aspek L / D padha, iku tekan luwih nyawiji, nanging kurang gesekan panas. The reciprocating Wobble-kothak disinkronake rotasi batang lan oscillation supaya saben revolusi meneng diiringi siji stroke lengkap maju lan mundur. njamin iki optimal distributif lan dispersive nyawiji karo konsumsi energi tithik. -

Biodegradable Jagung Pati Twin Meneng Extruder Mesin PLA pluru Plastic Making Machine

Laras saka Twin Meneng Extruder bisa dibukak ing menit. Iki ndadekake Éwah-éwahan produk, pangopènan lan riset gampang lan cepet. Loro-lorone ngawut-awut lan barel dirancang nggunakake prinsip bangunan pemblokiran. Konfigurasi meneng, persiyapan tong minyak, dipakani lan venting, layar ganti, cara saka pelletizing lan proses syarat, ing wawasan saka versatility mesin kang ing aplikasi umum liyane. -

Underwater PELLETIZER

Relatif kurang diregani dosing system.Accurate klompok silinder. kacepetan motor stepper miwiti saka 0,1 nganti 200 rpm.A pakan volumetrik, ing tangan liyane, ora adhedhasar volume ing kacepetan. -

spare parts kanggo Co-kneader

kita uga sumber sawetara spare parts kanggo Buss co-kneader customer lan x-senyawa co-kneader miturut requirements.we customer kang wis pirang-pirang set mesin CNC majeng lan peralatan Processing khusus kanggo Manufaktur kabeh spare parts iki. -

Lab-ukuran co-kneader

Meneng diameteripun: 45mm aspek L / D: 10-25 Stroke: 6.75mm motor utama: 22KW Max. kacepetan meneng: output Reference 500 Rpm: 10-60kg / h -

tong minyak extruder tetep

SHJ tetep laras Co-puteran meneng kembar extruder

Seri XINDA SHJ kembar meneng sing dibangun ing sistem modul. Ing kauntungan utama saka Desain modul iki konfigurasi Versatile. Tugas Processing bisa f tuntas karo mung sawetara tong minyak lan meneng variasi. -

clamshell tong minyak extruder

PSHJ clamshell tong minyak Co-puteran kembar meneng extruder.The tong minyak bisa dibukak ing menit. Iki ndadekake Éwah-éwahan produk, pangopènan lan riset gampang lan cepet. Loro-lorone ngawut-awut lan barel dirancang nggunakake prinsip bangunan pemblokiran. -

SKW 4-pesawat co-kneader

Four-pesawat Compounding System

Based on 3-flgiht compounding desain, XINDA develops teknologi anyar karo 4 penerbangan. The XINDA SKW kneader saben spiral wis bejat dening papat kesenjangan saben revolusi nemokake penerbangan kneading kanggo. Patang larik kneading lencana, kang individu dipasang ing tong minyak saben 90 degree, sing intermeshed karo penerbangan iki. Kanthi aspek L / D padha, iku tekan luwih nyawiji, nanging kurang gesekan panas. The reciprocating Wobble-kothak disinkronake rotasi batang lan oscillation supaya saben revolusi meneng diiringi siji stroke lengkap maju lan mundur. Njamin iki optimal distributif lan dispersive nyawiji karo konsumsi energi tithik.

Send your message to us:

Tulis pesen kene lan ngirim kanggo kita