-

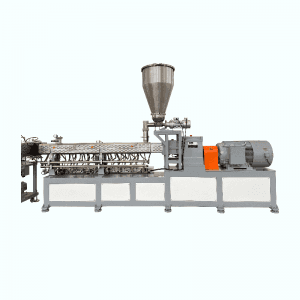

Nunui-waihoʻoluʻu PVC mea papa hele i huiʻia wili Extruder System

LOW ako, LOW puʻe, LOW mahana ¶ kiʻekiʻe wili ka hoʻokōʻana no kou COMPOUNDING pono ai -

Keʻena anakahi iki Compounder Twin hoʻohewa Extruder 35mm Pelletizing For Masterbatch ikea ai

Xinda he māhoe hoʻohewa extruder & ke kākoʻo '-kneader extruder no Keʻena noi, a hoʻohana no ka masterbatches, PVC compounding, filler masterbatches hoao, ect -

High Concerntrated Color Masterbatches Compounding Making Machine With Four Flights Screw

Description For Products Application For Co-kneader Output For Reference Layout for HFFR working process Output For Reference Model SKW-85 SKW-105 SKW-125 Co-kneader Screw Diameter 85 105 125 L/D Ratio 15-22 15-22 15-22 Max.Motor Power 600 600 600 Main Motor Power 110-160 200-280 350-450 Second-stage Screw Diameter 150 180 220 Second-stage Screw L/D Ratio 7 7 7 Max.Screw Speed 60 60 60 Second-stage Motor Power 55 75 110 Reference Output(KG) SKW-85 SKW-105 SKW-125 ... -

Concentrates Masterbatch Compounding Extruder And Pelletizing Line

XINDA Co-Kneader family SJW(M) System SJW(C) System SJW(T)System SJW(M) System Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Applic... -

Lau Flights Makeke-Kneader hui Extruder no HFFR a XLPE

XINDA e hoʻomōhala ana i hou 'enehana hou loa me ka 4 hoʻii. Ka XINDA SKW Kneader kēlā me kēiaʻoni iho ua wāwahiʻia ia e eha i wāhiʻia no kipi, e huli ana i ka wili hoʻii. Lau lālani o ka wili mau makia, a i pākahi hookomo i loko o ka barela no 90 degere, e intermeshed me kēia mau hoʻii. Me ka ia L / D hiʻohiʻona, e loaʻa iā ia nā oi hoʻohuihui, akā, e emi kū'ē wela. Ka pānaʻi wobble-pahu synchronizes ke kumu kuapo a me ka oscillation no laila, i kēlā me kēia kipi o ka hoʻohewa ua pu e kekahi piha hahauʻana i mua a me ka hope. Ua hōʻoia 'ia ai e pono ai distributive a dispersive hui pu iaʻi me ka palena haʻahaʻa ikehu hokii. -

Biodegradable palaoa pia Twin hoʻohewa Extruder Machine PLA anaʻana, lula ea Aloha Maker

Ka barela a Twin hoʻohewa Extruder hiki ke wehe i loko o minuke. Kēia i huahana changeover, malama a me ka noiʻi hoʻokēʻai a me ka maʻalahi. He mau nā kui nao a me nā barela i papahana hoʻohana 'ana i ka hale aeie rula. Ka hoʻohewa hoʻonohonohoʻia, pahu AUOO, e hanai ana oia a me venting, pale hoʻololi, ala o pelletizing a me ka kaʻina koi, ma ka noonoo ana o ka mīkini ka versatility i loko o nā mau noi. -

papa anuʻu loa kai PELLETIZER

KŘpa a haʻahaʻa ikamu dosing system.Accurate dosing paukūʻolokaʻa. Stepper Hawaii mämä holo e hoʻomaka ana mai 0,1 mai a hiki i 200 rpm.A volumetric feeder, ma ka kekahi lima, aole keia nānā 'ana i ka leo i ka holo. -

iāʻoe māhele no ka Makeke-kneader

mākou i hoolako i kekahi iāʻoe māhele no ka Customer ka kaʻa 'ohua' ke kākoʻo '-kneader, a m-hui ke kākoʻo'-kneader e like me ka Customer ka requirements.we i kekahi mau e puhi ia o ka holomua cnc machines a kūikawā aaioee lako a pan no ka manufacturing a pau i kēia iāʻoe wahi. -

Keʻena-me ka unahiʻole ke kākoʻo '-kneader

Hoʻohewa anawaena: 45mm L / D hiʻohiʻona: 10-25 mapuna: 6.75mm Main Hawaii: 22KW Max. Hoʻohewa māmā: 500 rpm Reference auaiaea: 10-60kg / h -

paa ka pahu extruder

SHJ haka pono barela Makeke-kaʻapuni māhoe hoʻohewa extruder

i kūkuluʻia ka XINDA SHJ māhoe hoʻohewa moʻo ma ka māhele kahua. Ka nui ia Morohiha o kēia māhele manao o ka versatile hoʻonohonohoʻia. Aaioee hana hiki e optimally a hooko aku la me wale i kekahi mau pahu a me ka hoʻohewa likeʻole. -

clamshell pāpale kila extruder

PSHJ Clamshell barela Makeke-kaʻapuni māhoe hoʻohewa extruder.The barela hiki ke wehe i loko o minuke. Kēia i huahana changeover, malama a me ka noiʻi hoʻokēʻai a me ka maʻalahi. He mau nā kui nao a me nā barela i papahana hoʻohana 'ana i ka hale aeie rula. -

SKW 4-holo ke kākoʻo '-kneader

Four-lele Compounding System

ka nānā 'ana ma luna o 3-flgiht compounding manao, XINDA e hoʻomōhala ana i hou' enehana hou loa me ka 4 hoʻii. Ka XINDA SKW Kneader kēlā me kēiaʻoni iho ua wāwahiʻia ia e eha i wāhiʻia no kipi, e huli ana i ka wili hoʻii. Lau lālani o ka wili mau makia, a i pākahi hookomo i loko o ka barela no 90 degere, e intermeshed me kēia mau hoʻii. Me ka ia L / D hiʻohiʻona, e loaʻa iā ia nā oi hoʻohuihui, akā, e emi kū'ē wela. Ka pānaʻi wobble-pahu synchronizes ke kumu kuapo a me ka oscillation no laila, i kēlā me kēia kipi o ka hoʻohewa ua pu e kekahi piha hahauʻana i mua a me ka hope. Ua hōʻoia 'ia ai e pono ai distributive a dispersive hui pu iaʻi me ka palena haʻahaʻa ikehu hokii.

Send your message to us:

E kākau i kou manaʻo ma 'aneʻi, a hoouna aku ia ia mai