-

Multi-xim PVC Flooring tebchaw Kneading Extruder System

QIS chais ya cov plaub, QIS SIAB, QIS KUB TAB SIS HIGH KNEADING EFFICIENCY RAU KOJ compounding xav tau kev pab -

Lab Micro Compounder Twin Ntsia Hlau Extruder hli 35 Pelletizing Rau Masterbatch Xeem

Xinda muaj ntxaib ntsia hlau extruder & co-Kneader extruder rau Lab daim ntawv thov, uas siv rau masterbatches, pvc compounding, muab tub lim masterbatches kuaj, ect -

High Concerntrated Color Masterbatches Compounding Making Machine With Four Flights Screw

Description For Products Application For Co-kneader Output For Reference Layout for HFFR working process Output For Reference Model SKW-85 SKW-105 SKW-125 Co-kneader Screw Diameter 85 105 125 L/D Ratio 15-22 15-22 15-22 Max.Motor Power 600 600 600 Main Motor Power 110-160 200-280 350-450 Second-stage Screw Diameter 150 180 220 Second-stage Screw L/D Ratio 7 7 7 Max.Screw Speed 60 60 60 Second-stage Motor Power 55 75 110 Reference Output(KG) SKW-85 SKW-105 SKW-125 ... -

Concentrates Masterbatch Compounding Extruder And Pelletizing Line

XINDA Co-Kneader family SJW(M) System SJW(C) System SJW(T)System SJW(M) System Melt pump is installed between the main extruder and the die. The benefits of melt pumps for extrusion operations includes the elimination of surging and other fluctuations, reduction of inconsistent melt temperatures, high pressures at lower product temperatures, compensation for the pumping or mixing capacity of the extruder, possibly reduced start-up times, and reduction of energy required by the extruder Applic... -

Plaub Flights Co-Kneader Tiabsis cov Extruder rau HFFR los yog XLPE

XINDA muaj tseeb tshiab technology nrog 4 flights. Lub XINDA SKW Kneader txhua kauv lawm los ntawm plaub ncua ib kiv puag ncig mus nrhiav tus kneading flights. Plaub kab ntawm kneading pins, uas yog ib lub zuj zus tso nyob rau hauv lub thoob ib 90 degree, yog intermeshed nrog cov flights. Nrog tib L / D ratio, nws achieves ntau nws, tab sis tsawg tsis sib haum xeeb thaum tshav kub kub. Lub reciprocating wobble-box synchronizes tus ncej kev sib hloov thiab oscillation kom txhua kiv puag ncig ntawm lub ntsia hlau yog nrog los ntawm ib tug tag nrho stroke rau pem hauv ntej thiab rov qab. Qhov no saib kuas pom distributive thiab dispersive nws muaj tsawg heev zog noj. -

Biodegradable Pob kws Starch Twin Ntsia Hlau Extruder Tshuab PLA Pellet Plastic Ua Tshuab

Lub chim ntawm Twin Ntsia Hlau Extruder yuav tsum qhib nyob rau hauv feeb. Qhov no ua rau cov khoom changeover, txij nkawm thiab kev tshawb fawb ceev thiab yooj yim. Ob screws thiab tej kas tham no yog tsim siv lub tsev thaiv hauv paus ntsiab lus. Cov ntsia hlau configuration, chim teeb, noj thiab venting, screen hloov, txoj kev pelletizing thiab txheej txheem uas yuav tsum tau, nyob rau hauv kev saib xyuas ntawm lub tshuab versatility nyob rau hauv lwm yam kev siv. -

underwater PELLETIZER

Kuj tsis tshua muaj luv nqi noj system.Accurate dosing lub tog raj kheej. Stepper lub cev muaj zog ceev pib los ntawm 0.1 mus txog 200 rpm.A volumetric feeder, rau lwm cov tes, qhov no raws li nyob rau hauv volume nyob rau hauv ceev. -

spare qhov chaw rau Co-Kneader

peb kuj muab ib co spare qhov chaw rau tus neeg muas zaub buss co-Kneader thiab x-compound co-Kneader raws li tus neeg muas zaub requirements.we muaj ob peb poob lawm tshaj cnc tshuab thiab tshwj xeeb ua cov khoom rau manufacturing tag nrho cov spare qhov chaw. -

Lab-scale co-Kneader

Ntsia Hlau txoj kab uas hla: 45mm L / D piv: 10-25 Stroke: 6.75mm Main lub cev muaj zog: 22KW Max. Ntsia Hlau ceev: 500 RPM Reference tso zis: 10-60kg / h -

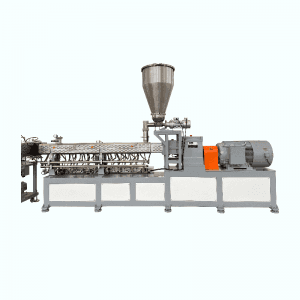

tsau chim extruder

SHJ tsau chim Co-rotating ntxaib ntsia hlau extruder

Lub XINDA SHJ ntxaib ntsia hlau series yog ua nyob rau hauv ib tug modular system. Qhov loj kom zoo dua ntawm no modular tsim yog lub ntau yam configuration. Ua paub tab yuav optimally tiav uas muaj ob peb chim thiab ntsia hlau variations. -

clamshell chim extruder

PSHJ Clamshell chim Co-rotating ntxaib ntsia hlau extruder.The chim yuav tsum qhib nyob rau hauv feeb. Qhov no ua rau cov khoom changeover, txij nkawm thiab kev tshawb fawb ceev thiab yooj yim. Ob screws thiab tej kas tham no yog tsim siv lub tsev thaiv hauv paus ntsiab lus. -

SKW 4-flight co-Kneader

Plaub-flight compounding System

Based on 3-flgiht compounding tsim, XINDA muaj tseeb tshiab technology nrog 4 flights. Lub XINDA SKW Kneader txhua kauv lawm los ntawm plaub ncua ib kiv puag ncig mus nrhiav tus kneading flights. Plaub kab ntawm kneading pins, uas yog ib lub zuj zus tso nyob rau hauv lub thoob ib 90 degree, yog intermeshed nrog cov flights. Nrog tib L / D ratio, nws achieves ntau nws, tab sis tsawg tsis sib haum xeeb thaum tshav kub kub. Lub reciprocating wobble-box synchronizes tus ncej kev sib hloov thiab oscillation kom txhua kiv puag ncig ntawm lub ntsia hlau yog nrog los ntawm ib tug tag nrho stroke rau pem hauv ntej thiab rov qab. Qhov no saib kuas pom distributive thiab dispersive nws muaj tsawg heev zog noj.

Send your message to us:

Sau koj cov lus no thiab xa nws mus rau peb