E PILI ANA IĀ MĀKOU

Ua Hopu

XINDA

Introduction

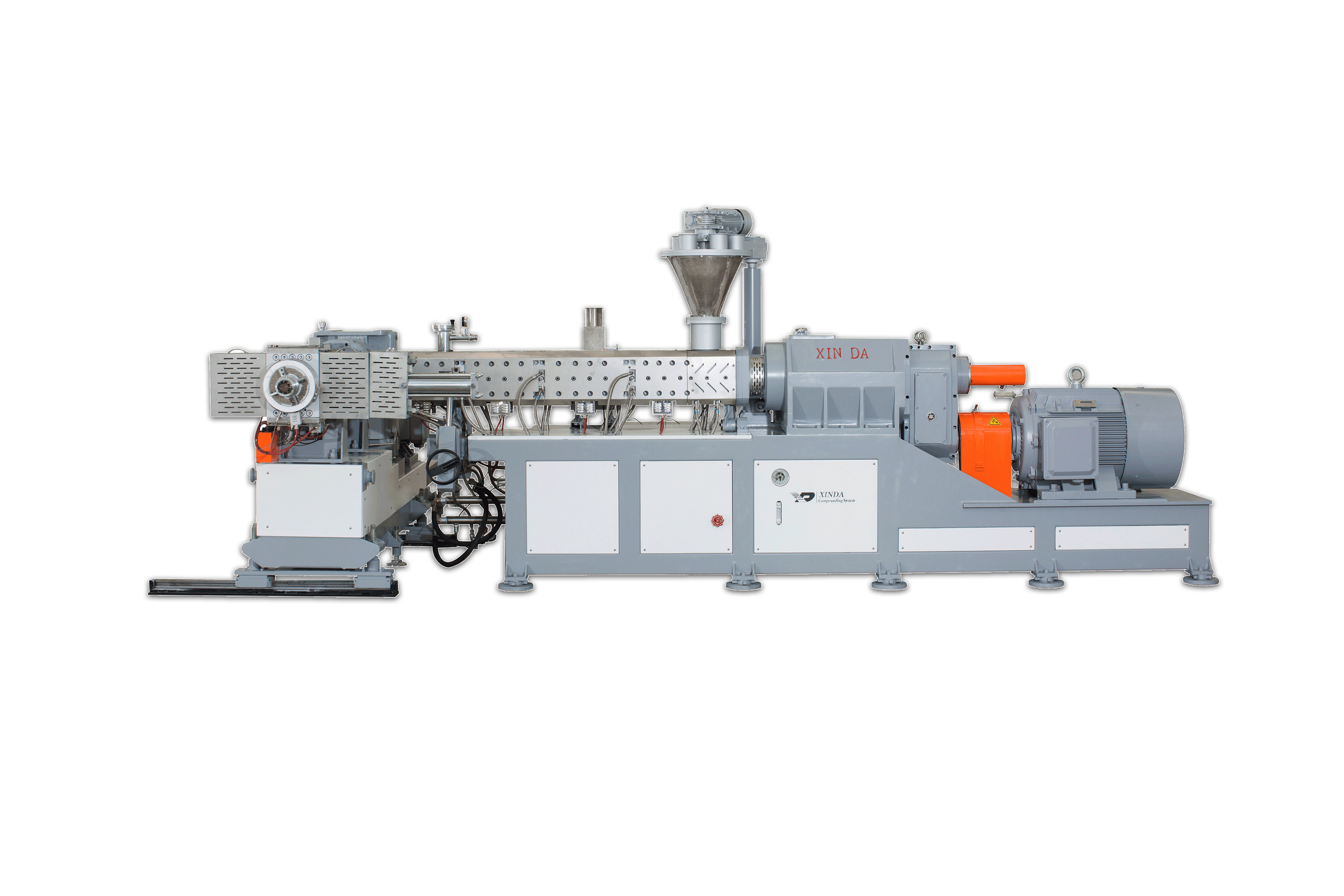

Hana compounding extruder mai 1996

25 makahiki ' ka hoao ana i ea compounding

2500compounding laina e holo ana ma 48 'āina

Aina hanau o Makeke-Kneaderma Kina

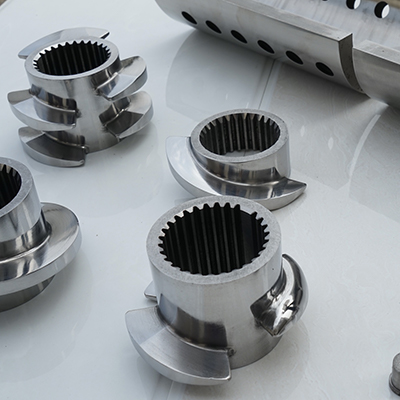

Palapala Sila Nui clamshell pahu māhoe hoʻohewa extruder

Over 40000sqm manufacturing kanu

-

-Hoʻokumu i ka 1996

-

-25 makahiki ka hoao ana

-

-+2500+ e holo mai ana laina

-

-+40000+ sqm MANUFACTURING kanu

huahana

HOU

News

Service First

-

Video Demo Show of Xinda Kneading Equipment

On March 26, 2021, Xinda demonstrated the full range of kneading extruders designed and produced by Xinda to customers at home and abroad in the form of video. This event shows the full range of SJW-45, 70, 100, 140, 200 three-flig...

-

This week, Xinda held a training lecture on the professional knowledge of plastic polymers

As a leading professional manufacturer of compounding equipment in China, in order to better improve product quality and serve Xinda’s customers. Xinda regularly organizes management and professional knowledge training for company employees. On the afternoon of Mar...