NIPA RE

awaridii

XINDA

Ọrọ Iṣaaju

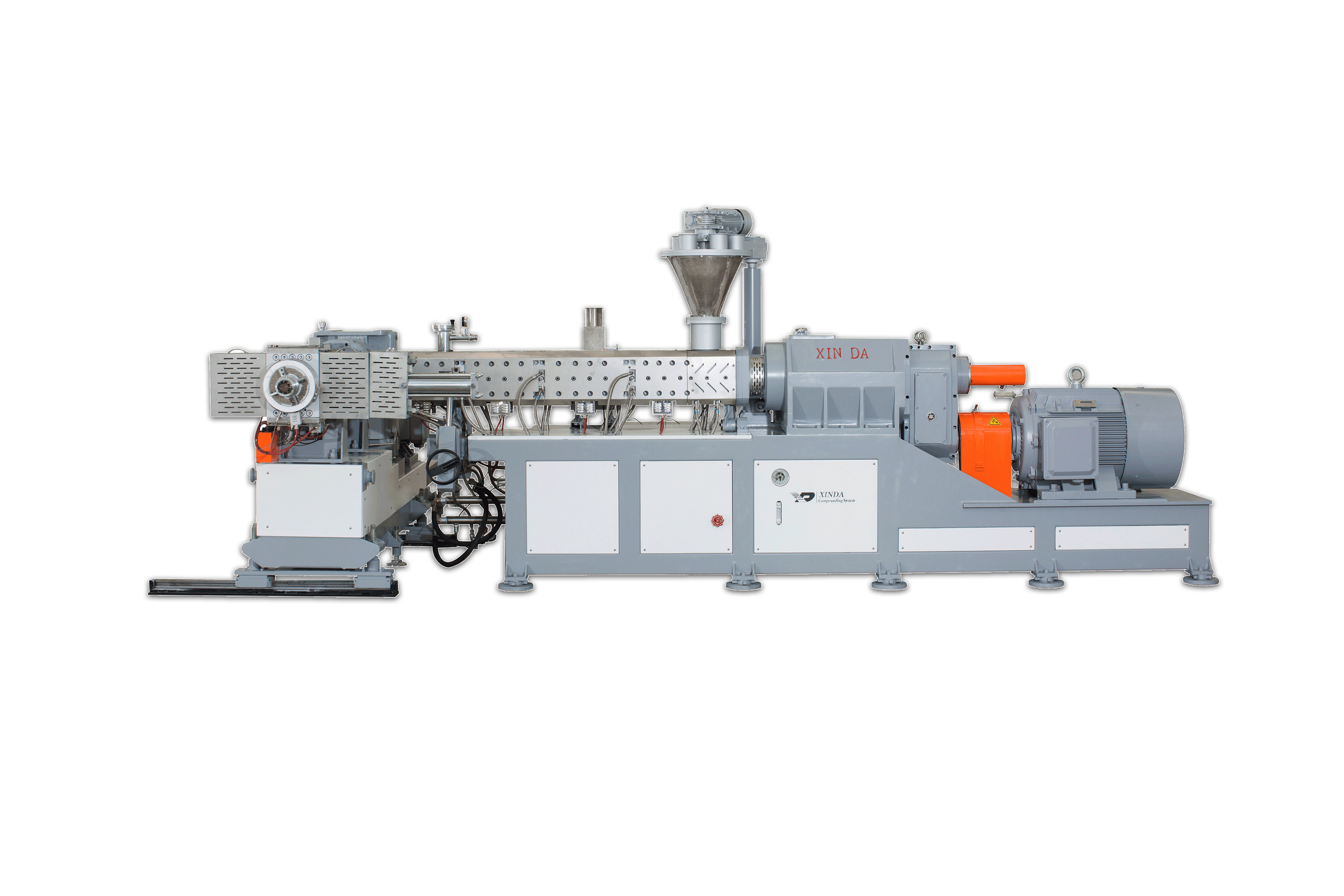

Lọpọ compounding extruder niwon 1996

25 years ' iriri lori ṣiṣu compounding

2500compounding ila ni ṣiṣiṣẹ ni 48 awọn orilẹ-ede

Birthplace ti Co-Kneader ni China

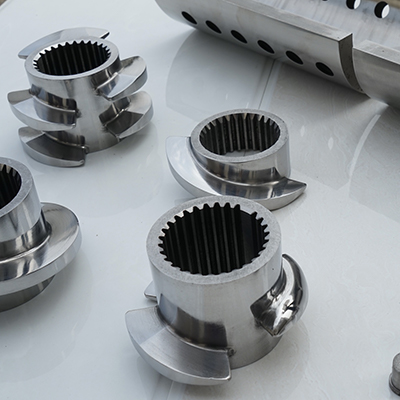

Idasilẹ gbamu agba ibeji dabaru extruder

Lori 40000sqm ẹrọ ọgbin

-

-Da ni 1996

-

-25 years iriri

-

-+2500+ yen ILA

-

-+40000+ sqm ẹrọ ọgbin

awọn ọja

Innovation

Awọn iroyin

Service First

-

Video Demo Show of Xinda Kneading Equipment

On March 26, 2021, Xinda demonstrated the full range of kneading extruders designed and produced by Xinda to customers at home and abroad in the form of video. This event shows the full range of SJW-45, 70, 100, 140, 200 three-flig...

-

This week, Xinda held a training lecture on the professional knowledge of plastic polymers

As a leading professional manufacturer of compounding equipment in China, in order to better improve product quality and serve Xinda’s customers. Xinda regularly organizes management and professional knowledge training for company employees. On the afternoon of Mar...