OM OS

Bryde igennem

Xinda

INTRODUKTION

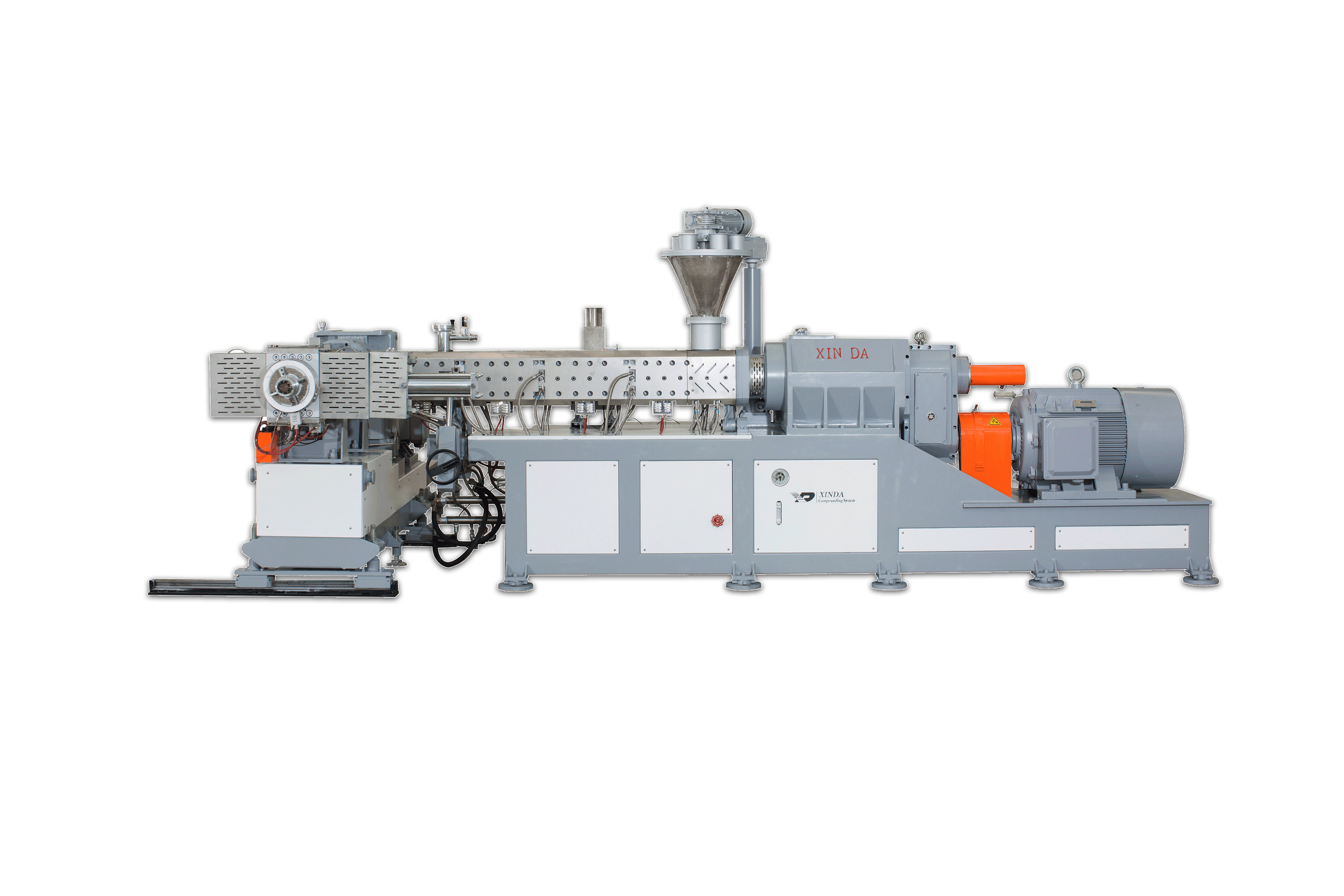

Fremstilling blandingsekstruderapparatet siden 1996

25 års erfaring på plastik blanding

2500kompoundering linjer kører i 48 lande

Fødested Co-Kneader i Kina

Patenteret clamshell tønde dobbeltsnekkeekstruder

Over 40000kvm fremstillingsanlæg

-

-Grundlagt i 1996

-

-25 års erfaring

-

-+End 2500 KØRSEL LINES

-

-+40000+ SQM MANUFACTURING PLANT

Produkter

Innovation

NYHEDER

service First

-

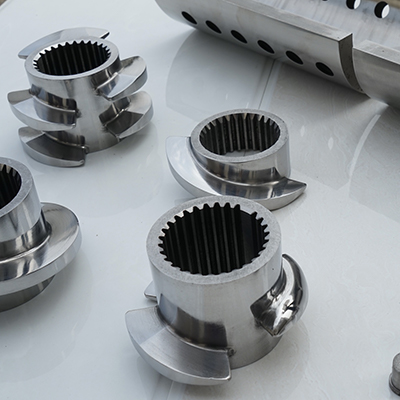

Video Demo Show of Xinda Kneading Equipment

On March 26, 2021, Xinda demonstrated the full range of kneading extruders designed and produced by Xinda to customers at home and abroad in the form of video. This event shows the full range of SJW-45, 70, 100, 140, 200 three-flig...

-

This week, Xinda held a training lecture on the professional knowledge of plastic polymers

As a leading professional manufacturer of compounding equipment in China, in order to better improve product quality and serve Xinda’s customers. Xinda regularly organizes management and professional knowledge training for company employees. On the afternoon of Mar...