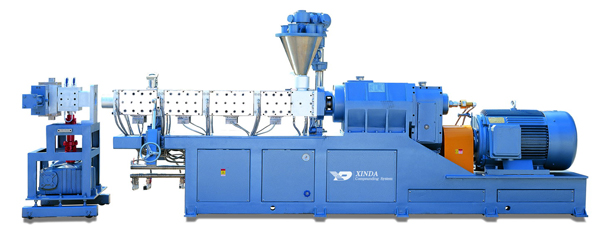

Multi-werna PVC Flooring Senyawa Kneading Extruder System

kulawarga XINDA Co-kneader

pump Nyawiji wis diinstal antarane extruder utama lan die. Keuntungan saka nyawiji Pumps kanggo operasi extrusion kalebu eliminasi surging lan fluktuasi liyane, abang Suhu nyawiji inconsistent, tekanan dhuwur ing Suhu produk ngisor, ganti rugi kanggo mompa utawa kapasitas nyawiji saka extruder ing, bisa suda kaping wiwitan-up, lan abang energi dibutuhaké déning extruder ing

Aplikasi:

--Color masterbatch / Concentrates

--High loading ngisi masterbatch

--Hot-nyawiji adhesive

plastik --Engineering compounding

elastomers --Engineered

|

model |

SJW-45 (M) |

SJW-70 (M) |

SJW-100 (M) |

SJW-140 (M) |

|

Meneng Diameter (MM) |

45 |

70 |

100 |

140 |

|

Length Diameter rasio |

15-25 |

15-25 |

15-25 |

15-25 |

|

Main Motor Power (KW) |

15-30 |

55-75 |

90-132 |

160-220 |

|

Max. Meneng Speed (RPM) |

500 |

500 |

500 |

500 |

|

Reference Output (KG / JAM) |

40-50 |

150-200 |

300-400 |

800-1000 |

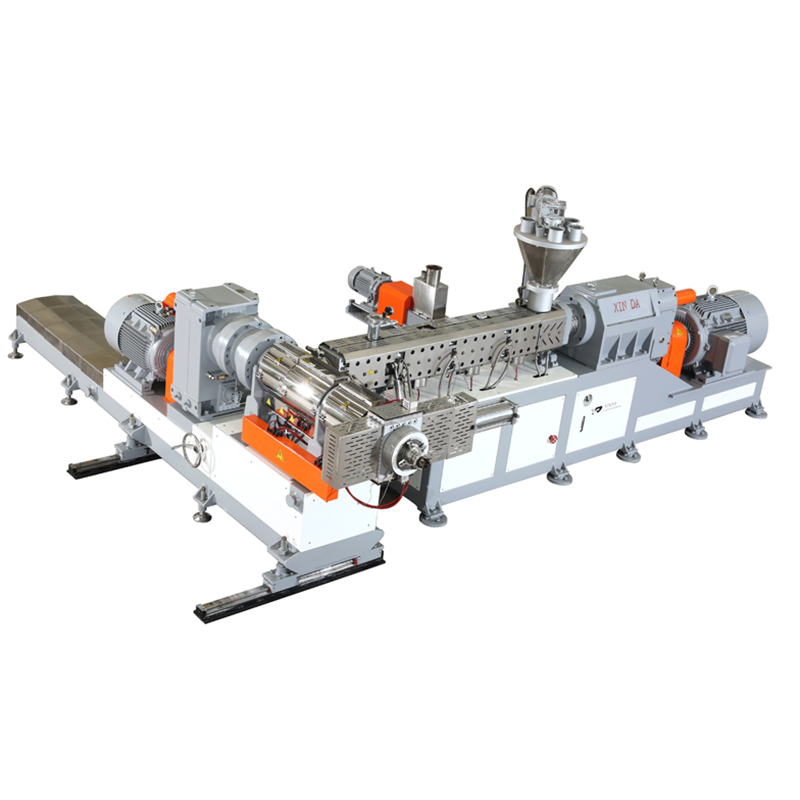

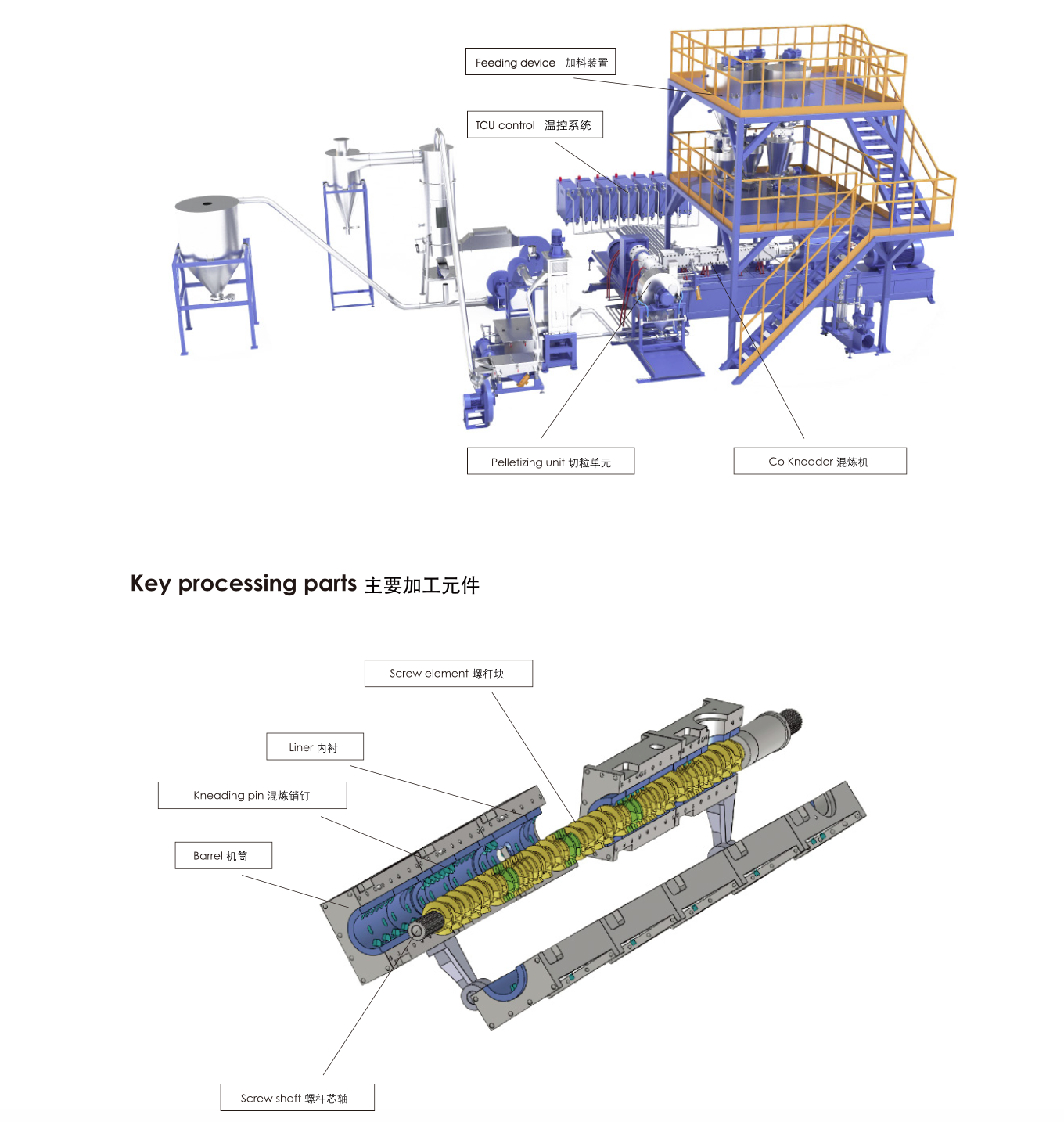

Jinis cascade saka Co-kneader line compounding wis kapérang saka Co-kneader mesin utama lan liyane ukuran gedhe siji meneng extruder. Simpenan bakal tumiba tataran siji extruder meneng kapindho sawise kebak buyar lan mbagekke ing Co-kneader. Iku bakal njamin bahan sing diproses ing suhu ngisor karo stabil extruding Proses wutuh dipérang dadi rong bagéan. Co-kneader ing pangisian daya saka kneading nalika kaping kalih siji meneng wis ngarahke ing extruding Sistem cascade banget mbiyantu kanggo entuk kualitas final luwih.

Aplikasi:

--PVC compounding pelletizing

--Shoe senyawa tunggal

--Wire senyawa kabel (XLPE, HFFR, senyawa Semi-konduktif, etc)

--Concentrated werna masterbatch

--Rubber, karet Final-kumpulan, Master kumpulan, senyawa Campuran

- elastomers

--Bio-degradable senyawa

--Metal injeksi ngecor

|

model |

SJW-45 (C) |

SJW-70 (C) |

SJW-100 (C) |

SJW-140 (C) |

SJW-200 (C) |

|

Meneng Diameter (MM) |

45 |

70 |

100 |

140 |

200 |

|

Length Diameter rasio |

20 ~ 25 |

20 ~ 25 |

20 ~ 25 |

20 ~ 25 |

20 ~ 25 |

|

Main Motor Power (KW) |

15 ~ 30 |

55 ~ 75 |

90 ~ 132 |

160 ~ 300 |

350 ~ 550 |

|

Liya-stageScrew Diameter (MM) |

60 |

120 |

150 |

200 |

280 |

|

Liya-tataran L / D |

7 ~ 8 |

7 ~ 8 |

7 ~ 8 |

7 ~ 8 |

7 ~ 8 |

|

Liya-tataran Power (KW) |

15 ~ 22 |

37 ~ 45 |

55 ~ 75 |

90 ~ 110 |

132 ~ 160 |

|

Max.Screw Speed (RPM) |

500 |

500 |

500 |

500 |

500 |

|

Reference Output (KG / JAM) |

40 ~ 70 |

150 ~ 250 |

300 ~ 500 |

800 ~ 1200 |

1900 ~ 3600 |

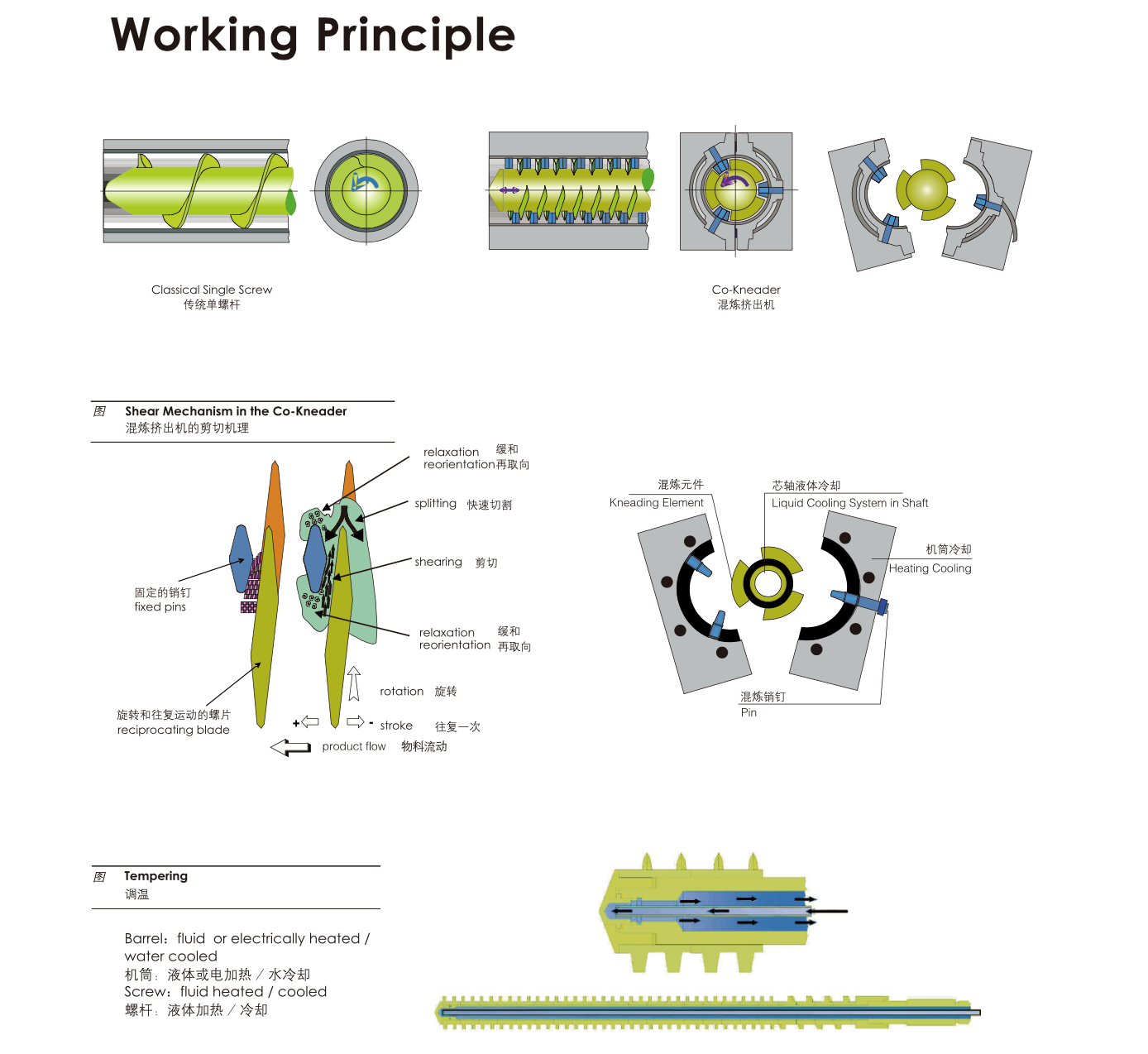

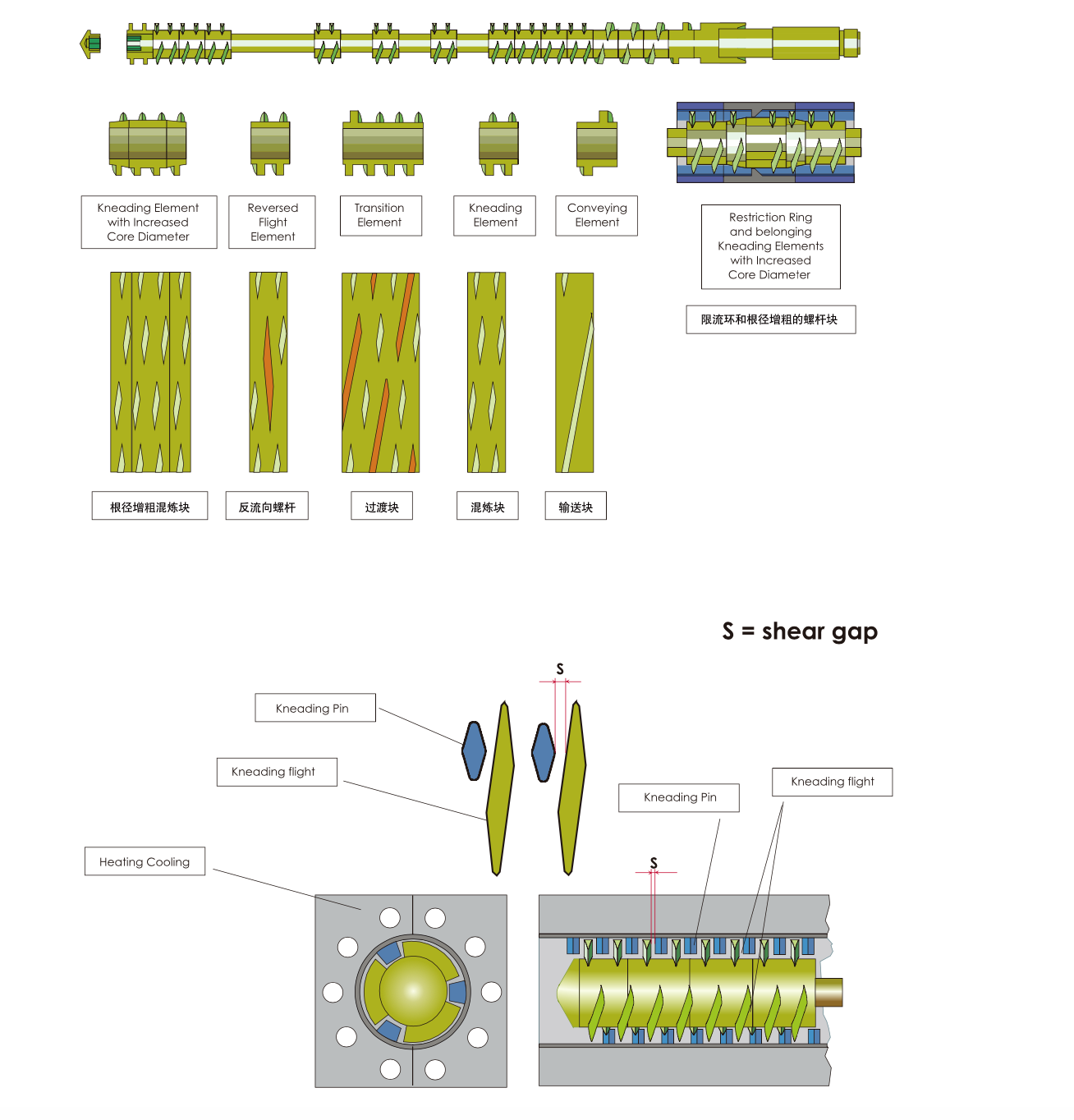

Kanthi prinsip kerja khusus lan cendhek L / aspek D XINDA Co-kneader seneng aplikasi sing wiyar ing lapangan thermoset senyawa plastik lan bubuk lapisan. Thermocouples bisa dipasang ing pins kneading dilatih ing macem-macem TCTerms beda bebarengan bagean proses kanggo njaluk kontak langsung karo nyawiji ing. Kombinasi saka panas Cairan lan sistem cooling lan ngawasi banget pas nyawiji ing

suhu ndadekake Co-kneader solusi banget sukses ing thermoset senyawa plastik lan bubuk nutupi toner.

Aplikasi:

plastik --Thermoset

--Powder nutupi lan toner

--Bakelite ngecor senyawa

--Polymer: epoxy, acrylic, urethane, polyster, etc

|

model |

SJW-45 (T) |

SJW-70 (T) |

SJW-100 (T) |

SJW-140 (T) |

SJW-200 (T) |

|

Meneng Diameter (MM) |

45 |

70 |

100 |

140 |

200 |

|

Length Diameter rasio |

7-15 |

7-15 |

7-15 |

7-15 |

7-15 |

|

Main Motor Power (KW) |

15-30 |

55-75 |

90-132 |

160-220 |

350-450 |

|

Max. Meneng Speed (RPM) |

500 |

500 |

500 |

500 |

500 |

|

Reference Output (KG / JAM) |

40-100 |

100-400 |

300-600 |

500-1000 |

1000-2000 |

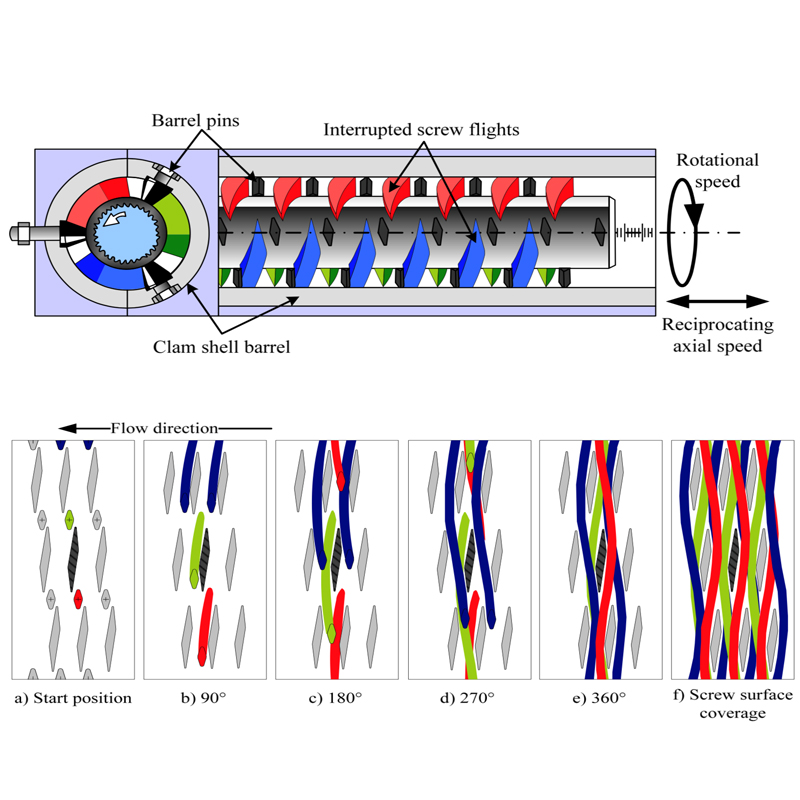

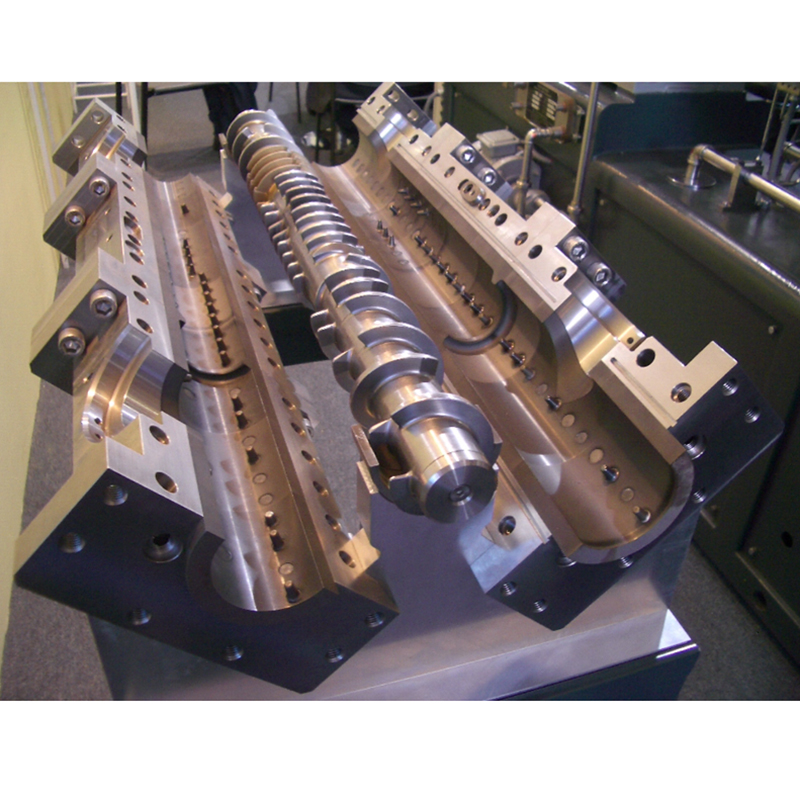

Description Kanggo Products

Asas Pakaryan Kanggo Co-kneader

Advantage Kanggo Four Tiket Co-kneader

- --Lower input energi, murah Suhu nyawiji

- --Extremely podho nyawiji, ora mancep nyukur, perawatan witjaksono matrik Polymer

- jurusan --High saka timer wiping lan duwe titik mati

- --Dispersive nyawiji tanpa ngancurake fllers alus

- loadings volumetrik --High saka fllers lan aditif

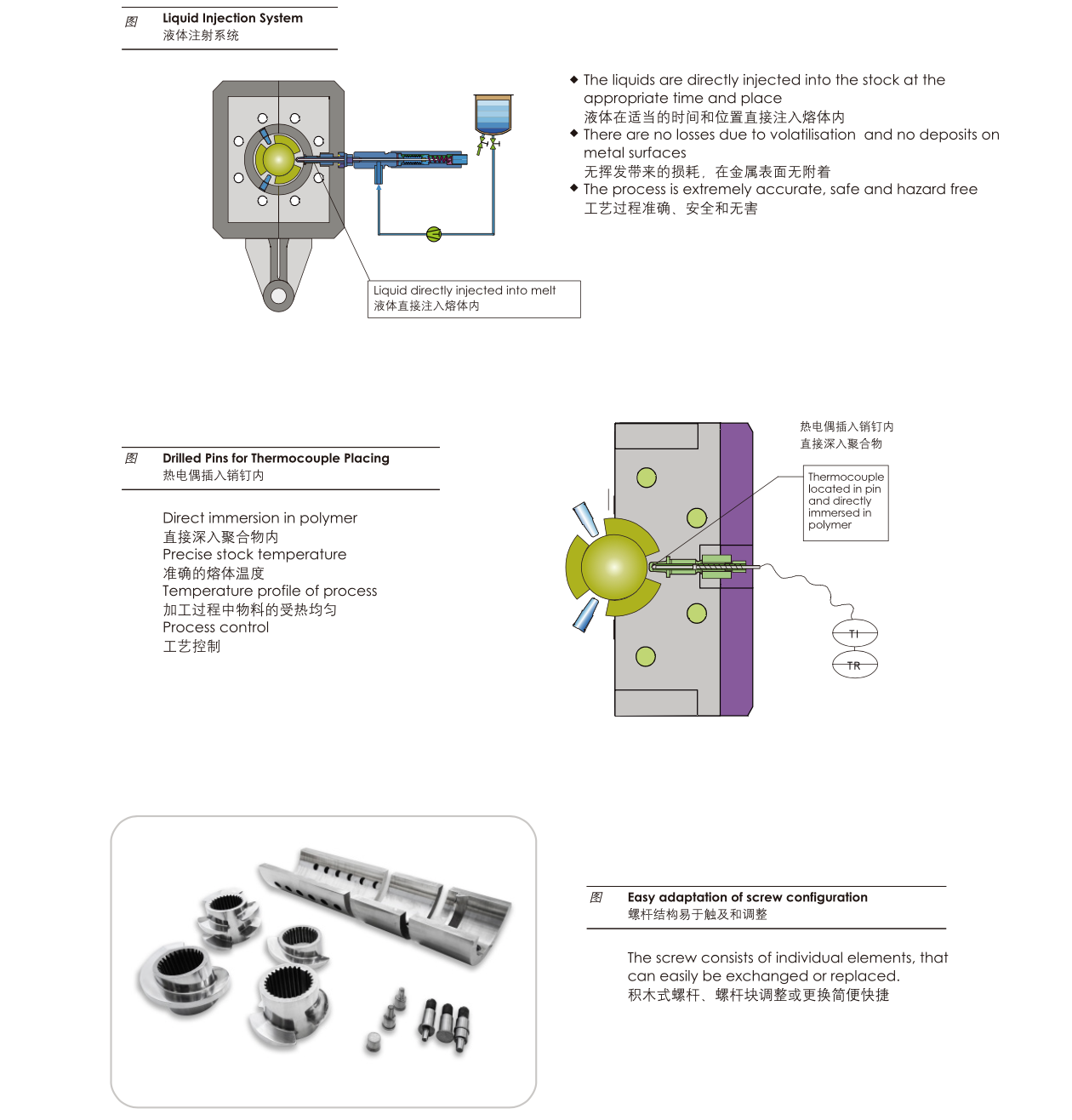

- campuran --Efficient komponen Cairan

- aplikasi --Broad kanggo compounding tanpa ganti hardware

- --Axially kabuka pamisah tong minyak njamin ease saka reresik lan pangopènan cepet

- bagean --Replacement, kayata ngawut-awut, laras lining lan lencana bisa diganti individu

Aplikasi saka Twin Meneng Extruder :

- Various ngisi plastik anorganik, Polymer campuran (alloy plastik), pewarna plastik, ECT

- Various engineering pitulungan plastik saka serat kaca, pelet semangat-retartant

- Various antibacterial, terisolasi, bahan toughening Efesus tartamtu

- Cahya / biologi bahan film degradable, amylum plastik degradable lan multi-fungsi bahan film anti-pedhut, etc.

- materi tartamtu kanggo otomotif lan perabot rumah tangga lan bahan kabel, etc

- elastomers Themoplastic, kayata TPR, TPE, lan SBS, etc

- pelet regenerate kanggo PVC airproof bêsik, lim Thermo-telat, etc

|

model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Meneng Diameter:

MM |

21.7

|

35,6

|

50,5

|

62,4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter rasio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output torsi saben batang: Nm

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG / JAM

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Meneng Diameter:

MM |

35,6

|

50,5

|

62,4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter rasio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output torsi saben batang: Nm

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG / JAM

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|