Wholesale Price Conductive Compound Extruder - fixed barrel extruder – Xinda

Wholesale Price Conductive Compound Extruder - fixed barrel extruder – Xinda Detail:

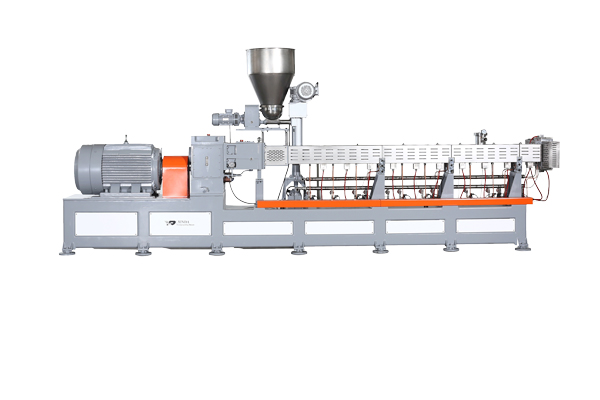

SHJ fixed barrel Co-rotating twin screw extruder

SHJ Co-rotating Twin Screw Extruder

The XINDA SHJ twin screw series are fixed barrel design co-rotating twin screw extruder based on building block. The segmented screw geometry can be versatile for multiple application of compounding for plastic and rubber. XINDA has provided customers with different options in the gearbox including high torque gearbox. XINDA can provide enough stability and durability for the mass production of compounding process.

The pelletizing systems are also optional including water strand pelletizing, water ring pelletizing, hot die face cutting & air cooling, strand pelletizing with air cooling belt, underwater pelletizing system, which is subject to the capacity, material formula and final granules requirement

Application:

1. Color masterbatch/Concentrates

2. High loading filler masterbatch

3. Hot-melt adhesive

4. Engineering plastics compounding

5. Engineered elastomers

6. Food Additives

7. Bio-degradable compounds

8. HFFR, XLPE, semi conductive Cable compounds

| Model | SHJ-20 | SHJ-35 | SHJ-50 | SHJ-65 | SHJ-75 | SHJ-95 |

| Screw Diameter: MM | Φ21.7 | Φ35.6 | Φ50.2 | Φ62.4 | Φ71 | Φ91 |

| Central Distance | 18 | 30 | 42 | 52 | 60 | 78 |

| Length Diameter Ratio | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power: KW | 4-5.5 | 22-45 | 75-110 | 110-185 | 160-280 | 180-355 |

| Max. Screw Speed: RPM | 600 | 600 | 600 | 600 | 600 | 600 |

| Output Torque per Shaft N.m | 32-43 | 175-358 | 579-875 | 875-1472 | 1273-2228 | 1432-2825 |

| Reference Output: KG/HOUR | 5-20 | 20-80 | 80-200 | 150-350 | 300-600 | 700-1500 |

| Model | C-SHJ-35 | C-SHJ-50 | C-SHJ-65 | C-SHJ-75 | C-SHJ-95 |

| Screw Diameter: MM | Φ35.6 | Φ50.5 | Φ62.4 | Φ71 | Φ91 |

| Central Distance | 30 | 42 | 52 | 60 | 78 |

| Length Diameter Ratio | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power KW | 22-45 | 75-132 | 110-250 | 160-355 | 315-650 |

| Max. Screw Speed:RPM | 800 | 800 | 800 | 800 | 800 |

| Output Torque per Shaft N.m | 131-269 | 448-788 | 657-1492 | 955-2119 | 1880-3880 |

| Reference Output: KG/HOUR | 150-300 | 200-500 | 400-800 | 500-1000 | 800-2000 |

Product detail pictures:

Related Product Guide:

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Wholesale Price Conductive Compound Extruder - fixed barrel extruder – Xinda , The product will supply to all over the world, such as: Sydney, Bhutan, Kuwait, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.