Good Quality Spare Parts Service – spare parts for Co-kneader – Xinda

Good Quality Spare Parts Service – spare parts for Co-kneader – Xinda Detail:

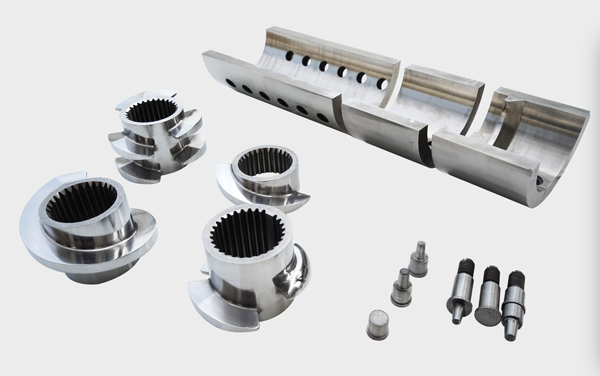

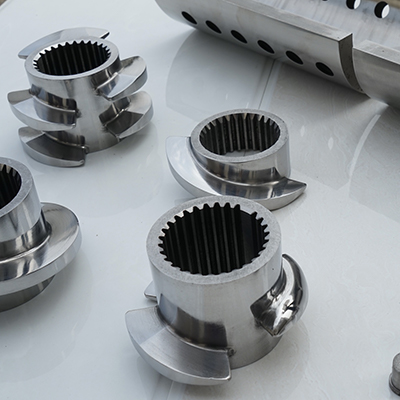

spare parts for co-kneader

jiangsu xinda tech limited specialized in the manufacture of co-kneader modular screw shaft, screw elements, barrel, and pins relating to various types that lies between ø30mm to ø200mm. we had several sets of advanced cnc machines and special processing equipment for manufacturing all these spare parts.

meanwhile, we also supply some spare parts for customer’s buss co-kneader and x-compound co-kneader according to customer’s requirements

xinda co-kneader screw elements, pins and barrel

| Xinda Co-kneader | Screw elements | Barrel | Pins | |

| SJW-45 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-70 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-100 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-140 | As per xinda drawing | As per xinda drawing | As per xinda drawing | |

| SJW-200 | As per xinda drawing | As per xinda drawing | As per xinda drawing |

Product detail pictures:

Related Product Guide:

We take pleasure in a really excellent name amongst our shoppers for our exceptional product or service excellent, competitive rate and also the greatest services for Good Quality Spare Parts Service – spare parts for Co-kneader – Xinda , The product will supply to all over the world, such as: Mongolia, South Korea, Cairo, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Biodegradable Corn Starch Twin Screw Extruder Machine PLA Pellet Plastic Making Machine

The barrel of Twin Screw Extruder can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, feeding and venting, screen changing, way of pelletizing and process requirements, in consideration of the machine’s versatility in other general applications.

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Write your message here and send it to us

Send your message to us:

Write your message here and send it to us