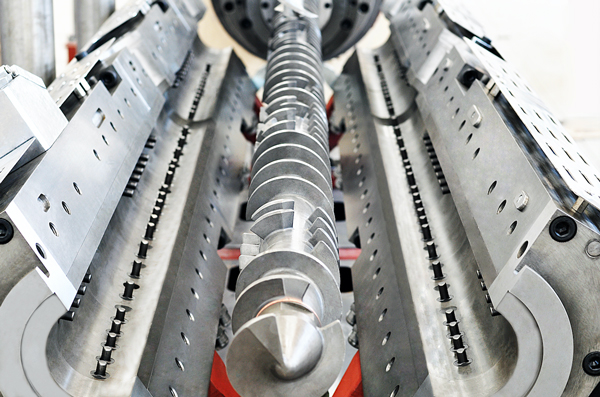

Europe style for China Wholesale Plastic Twin Double Screw Extruder PVC Wall Ceiling Panel Profile Extruder Making Machine

The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for Europe style for China Wholesale Plastic Twin Double Screw Extruder PVC Wall Ceiling Panel Profile Extruder Making Machine, Should you pursuit the Hi-quality, Hi-stable, Aggressive price tag parts, business name is your most effective choice!

The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for twin screw extruder machine price, types of twin screw extruder, zsk twin screw extruder, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

Description For Products

Application For WKS Co-kneader

Application

Output For Reference

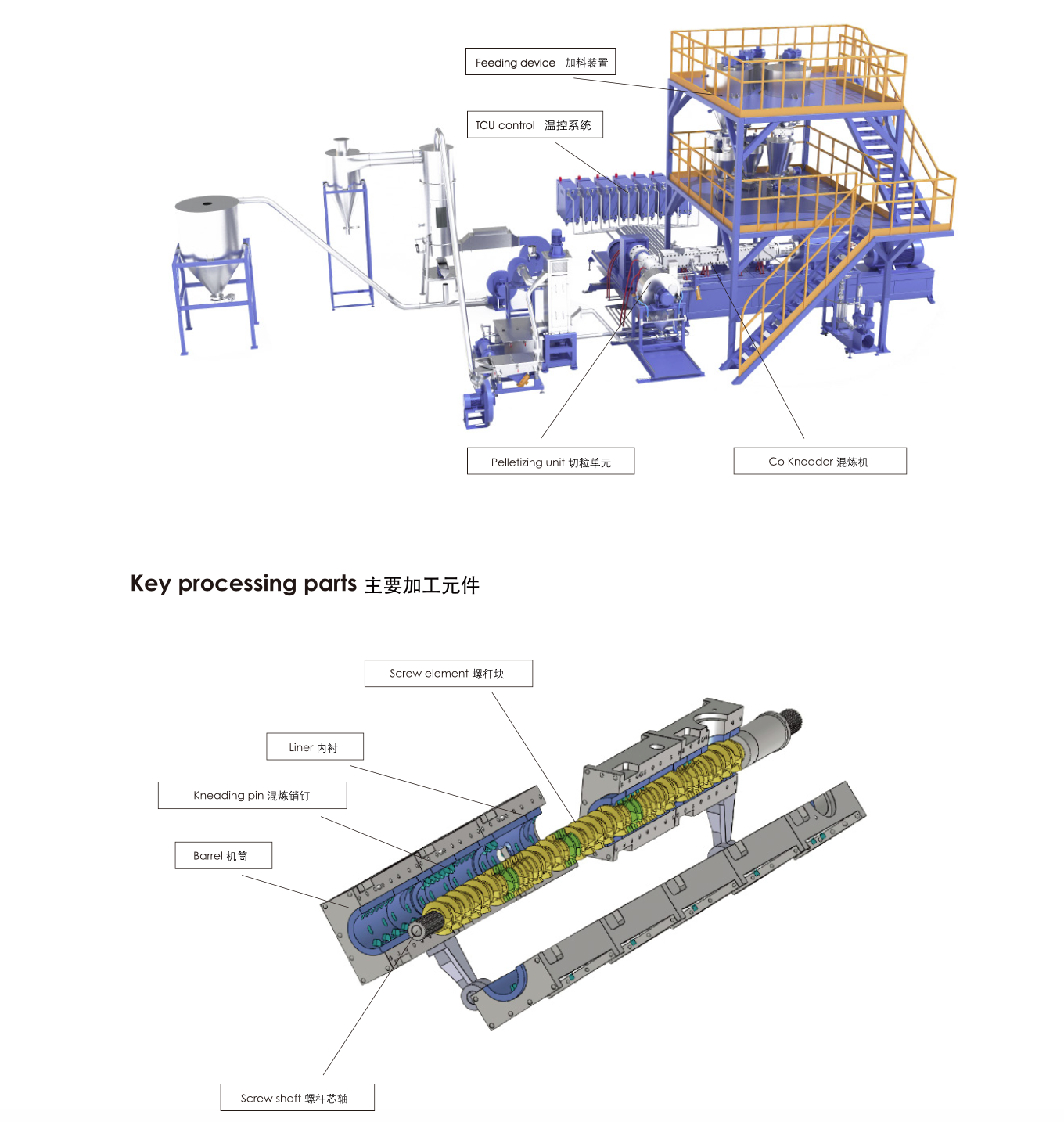

Layout for HFFR working process

Application

–PVC compounds

–Soft PVC cable compounds for sheathing, insulation, bedding

–Soft PVC compounds

–Rigid PVC compounds

Output For Reference

| Model | WKS-100 | WKS-120 |

| Co-kneader Screw Dia. | 100 | 120 |

| L/D Ratio | 15 | 15 |

| Max. Screw Speed | 500 RPM | 500 RPM |

| Main Motor Power | 160-200 KW | 220-280 KW |

| Second-stage Screw Dia. | 200mm | 220mm |

| Second-stage Screw L/D | 7 | 7 |

| Max. Screw Speed | 60 RPM | 60 RPM |

| Second-stage Motor Power | 55-75 KW | 90 KW |

| Reference output (kg/h) | 1000-1500 | 1500-2000 |

Layout for HFFR working process

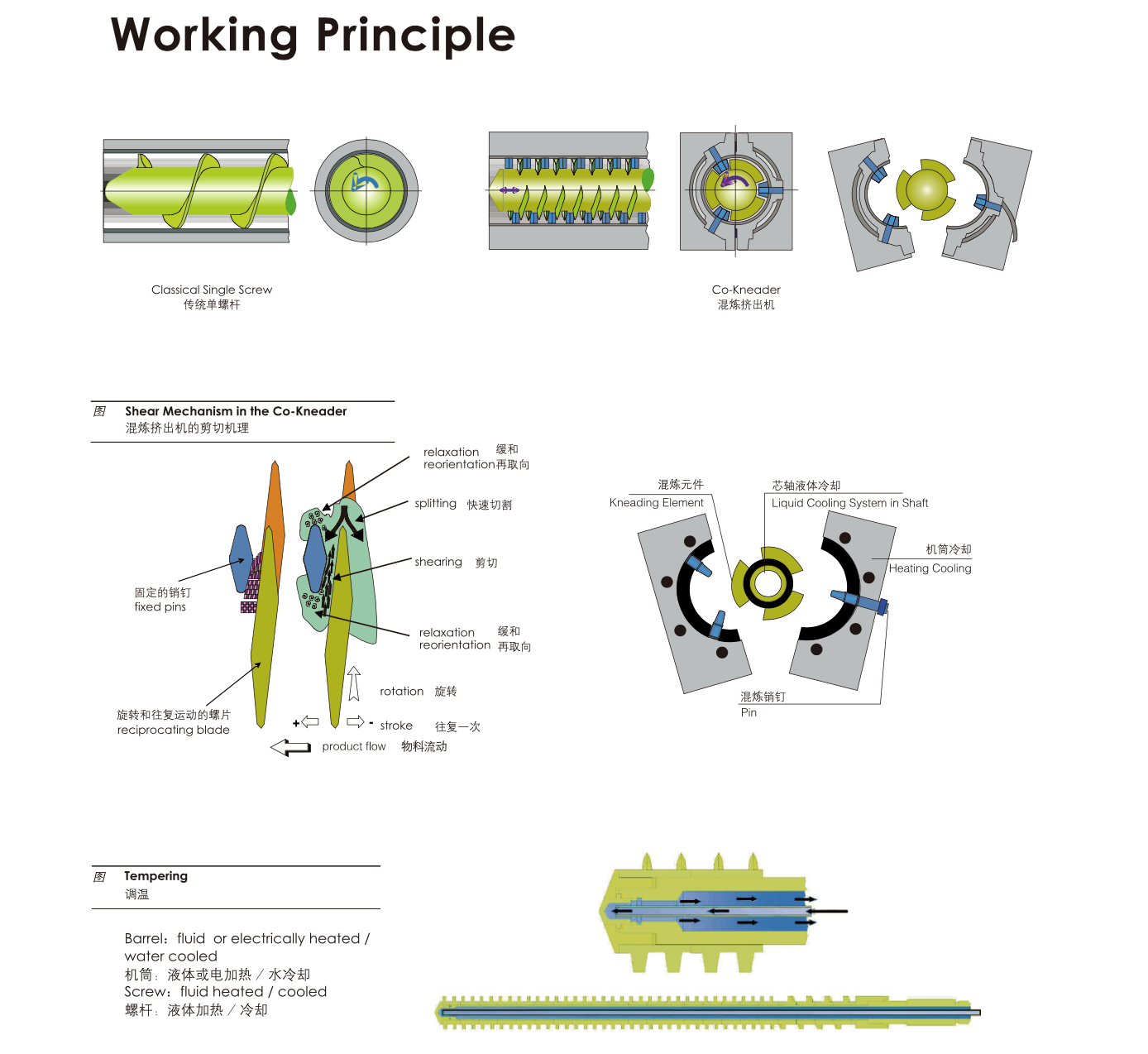

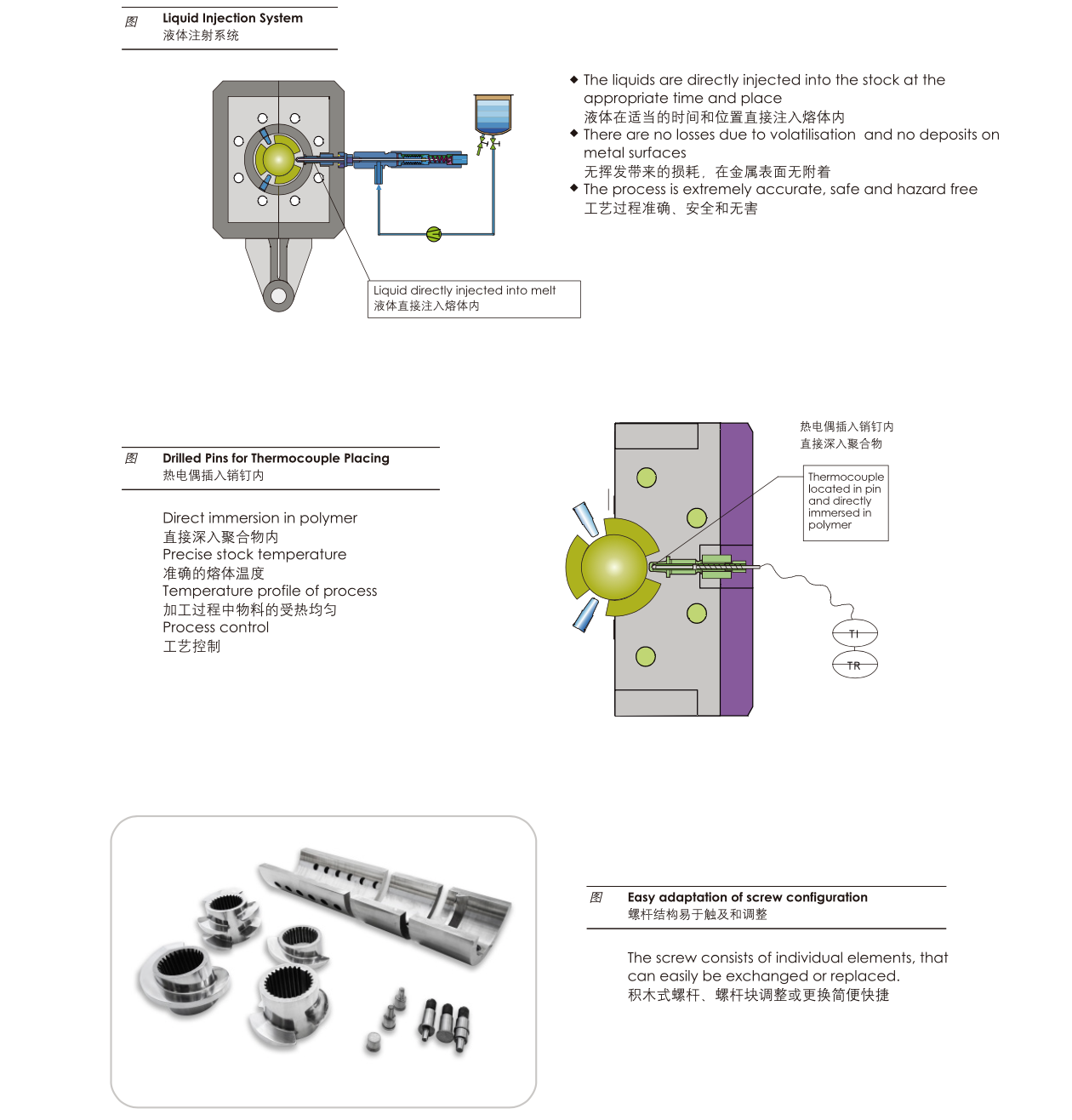

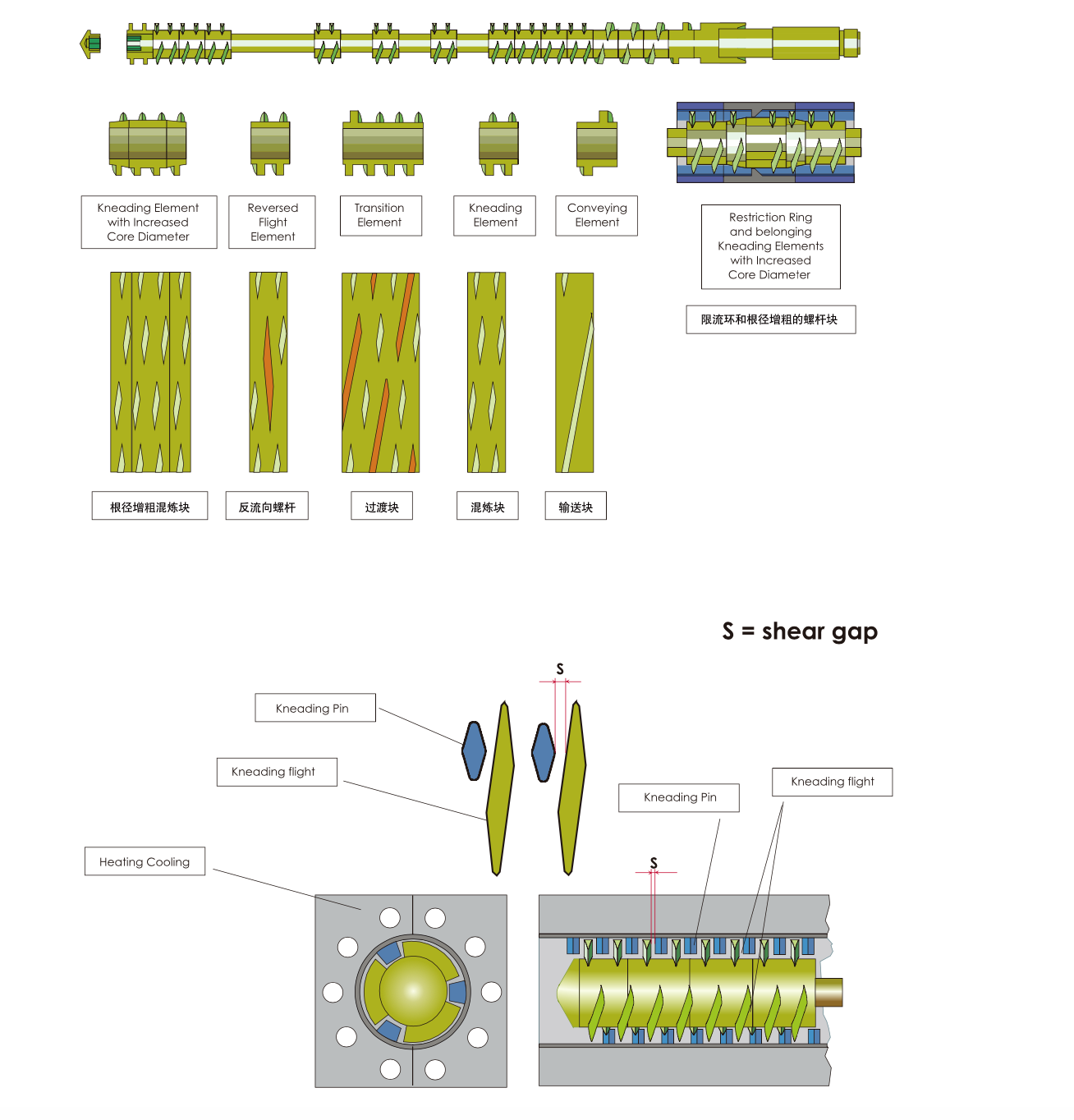

Working Principle For Co-kneader

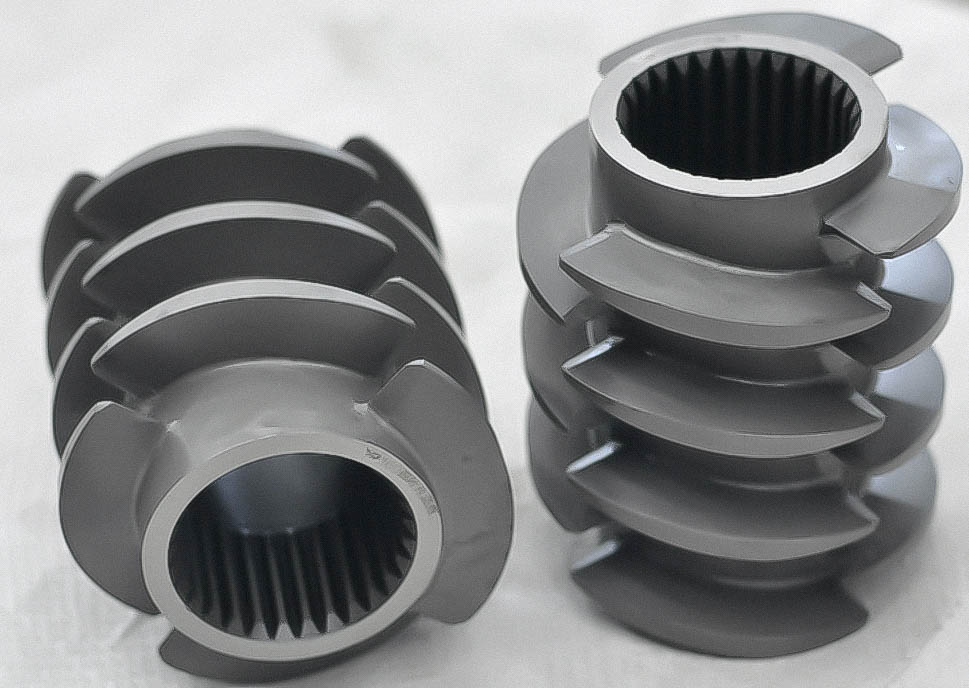

Advantage For Four Flights Co-kneader

Feature

Feature

- The XINDA WKS 4-Flight Co-kneader is only designed for PVC compounding and pelletizing, with target capacity 1500-2000kg/h for PVC cable compounds for a single compounding line.–Typical highlights and benefits of XINDA WKS 4-flight Co-kneader:

–Optimized intake section: No forcing feeding, large inlet opening, effective backward degassing, -improve material transport

–4 row of flights increase shear surface, produce more shear energy

–Improve conveying stability by overlapping flights

–No open gap between flights and pins

Factory Introduction

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|