2019 Good Quality Blowing Masterbatch Machine - UNDERWATER PELLETIZER – Xinda

2019 Good Quality Blowing Masterbatch Machine - UNDERWATER PELLETIZER – Xinda Detail:

Volumetric feeder

A volumetric feeder, on the other hand, does this based on volume in speed.

A volumetric feeder is a dosing system that supplies the production system with a certain volume of material in a set timeframe, based on the so-called displacement principle. In contrast to a gravimetric feeder, the dosing speed of a volumetric feeder should be selected manually, which may vary based on the nature of the raw input materials. For example, masterbatch requires a different speed compared to dosing of liquid or powder input material.

For smaller production processes and companies who are looking to save on dosing equipment, a volumetric feeder is favoured over a gravimetric feeder. Yet, a gravimetric feeder enables one to save heavily on the input material by a more precise feeding process. This means that a gravimetric feeding system usually provide for a higher return of investment (ROI) on a long-term basis.

Volumetric feeder

Advantages

Relatively low priced dosing system

Accurate dosing cylinder

Stepper motor speed starting from 0.1 up to 200 rpm

Disadvantages

Manual recalibration required

Limited control over your product quality

No monitoring and reporting options

Cannot automatically compensate for fluctuations in density

Sensitive to material build-up

No automatic detection of material supply interruption

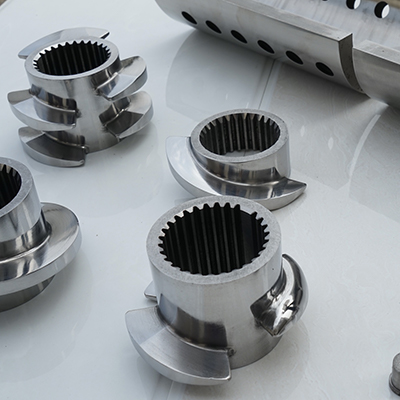

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 2019 Good Quality Blowing Masterbatch Machine - UNDERWATER PELLETIZER – Xinda , The product will supply to all over the world, such as: Jordan, Florida, Belgium, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.