100% Original Professional Twin Screw Extruder Pla - clamshell barrel extruder – Xinda

100% Original Professional Twin Screw Extruder Pla - clamshell barrel extruder – Xinda Detail:

PSHJ Clamshell barrel Co-rotating twin screw extruder

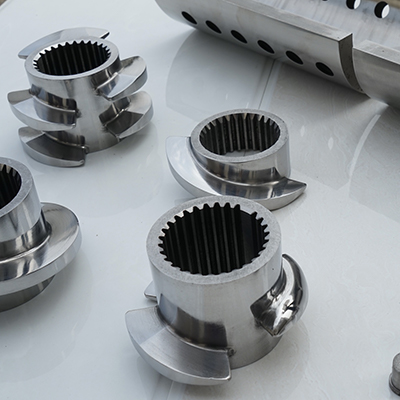

The barrel can be opened in minutes. This makes product changeover, maintenance and research fast and easy. Both screws and barrels are designed using the building block principle.

Modular construction

The XINDA PSHJ twin screw series are built on a modular system. The major advantage of this modular design is the versatile configurations. Processing tasks can be optimally accomplished with only a few barrel and screw variations.

Barrel Section- Separately controlled

The modular principle of the barrel permits precise sequencing for each application. Each barrel section’s temperature can be set separately. Electrical heater shells provide for heating, cooling is obtained with water.

Standard barrels

The freely selectable order of screws and kneading elements assure the process sections mating the process configuration. Thus, different process zones can be set up interchangeably, according to the requirements for: Conveying; Plasticizing; Mixing and shearing; Homogenizing; Degassing; Pressure building.

Application:

1. Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, etc.

2. Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, etc.

3. Various engineering plastic reinforcement of glass fiber, flame-retardant pellets

4. Various antibacterial, insulated, toughening materials for specific uses

5. Light/biology degradable film materials, asylum degradable plastics and multi-functional anti-fog film materials, etc.

6. Specific material for automobiles and household appliance and cable materials, etc.

7. Thermoplastic elastomers, such as TPR, TPE, and SBS, etc.

8. Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc.

| Model | PSHJ-20 | PSHJ-35 | PSHJ-50 | PSHJ-65 | PSHJ-75 | PSHJ-95 |

| Screw Diameter: MM | Φ21.7 | Φ35.6 | Φ50.5 | Φ62.4 | Φ71 | Φ91 |

| Central Distance | 18 | 30 | 42 | 52 | 60 | 102 |

| Length Diameter Ratio | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power | 4-5.5 | 22-45 | 75-110 | 110-185 | 160-280 | 180-355 |

| Max. Screw Speed: RPM | 600 | 600 | 600 | 600 | 600 | 600 |

| Output Torque per Shaft N.m | 32-43 | 175-358 | 597-875 | 875-1472 | 1273-2228 | 1365-2825 |

| Reference Output: KG/HOUR | 5-20 | 20-80 | 80-200 | 150-350 | 300-600 | 800-1500 |

| Model | C-PSHJ-35 | C-PSHJ-50 | C-PSHJ-65 | C-PSHJ-75 |

| Screw Diameter: MM | Φ35.6 | Φ50.5 | Φ62.4 | Φ71 |

| Central Distance | 30 | 42 | 52 | 60 |

| Length Diameter Ratio | 28-52 | 28-52 | 28-52 | 28-52 |

| Main Motor Power | 22-45 | 75-132 | 110-250 | 160-355 |

| Max. Screw Speed: RPM | 800 | 800 | 800 | 800 |

| Output Torque per Shaft N.m | 131-269 | 448-788 | 657-1492 | 955-2119 |

| Reference Output: KG/HOUR | 150-300 | 200-500 | 400-800 | 500-100 |

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for 100% Original Professional Twin Screw Extruder Pla - clamshell barrel extruder – Xinda , The product will supply to all over the world, such as: Macedonia, New Zealand, Ethiopia, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Application of the Twin Screw Extruder:

- Various plastic inorganic filler, polymer blending (plastic alloy), plastic coloring, ect

- Various engineering plastic reinforcement of glass fiber, flame-retartant pellets

- Various antibacterial, insulated, toughening materials for specific uses

- Light/biology degradable film materials, amylum degradable plastics and multi-functional anti-fog film materials, etc.

- Specific material for automobiles and household appliance and cable materials, etc

- Themoplastic elastomers, such as TPR, TPE, and SBS, etc

- Regenerate pellets for PVC airproof pieces, thermo-soluble glue, etc

|

Model

|

PSHJ-20

|

PSHJ-35

|

PSHJ-50

|

PSHJ-65

|

PSHJ-75

|

PSHJ-127

|

|

Screw Diameter:

MM |

21.7

|

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

18

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

28-52

|

|

Main Motor Power

|

4-5.5

|

22-45

|

75-110

|

110-185

|

160-280

|

90-160

|

|

Max.Screw Speed:

RPM |

600

|

600

|

600

|

600

|

600

|

600

|

|

Output Torque per Shaft:N.m

|

32-43

|

175-358

|

597-875

|

875-1472

|

1273-2228

|

850-1528

|

|

Reference Output: KG/HOUR

|

5-20

|

20-80

|

80-200

|

150-350

|

300-600

|

800-1500

|

|

Max.Screw Speed:

RPM |

800

|

800

|

800

|

800

|

500

|

|

Model

|

C-PSHJ-35

|

C-PSHJ-50

|

C-PSHJ-65

|

C-PSHJ-75

|

C-PSHJ-127

|

|

Screw Diameter:

MM |

35.6

|

50.5

|

62.4

|

71

|

126

|

|

Central Distance

|

30

|

42

|

52

|

60

|

102

|

|

Length Diameter Ratio

|

28-52

|

28-52

|

28-52

|

28-52

|

13-18

|

|

Main Motor Power

|

22-45

|

75-132

|

110-250

|

160-355

|

90-160

|

|

Output Torque per Shaft:N.m

|

131-269

|

448-788

|

657-1492

|

955-2119

|

850-1528

|

|

Reference Output: KG/HOUR

|

150-300

|

200-500

|

400-800

|

500-100

|

800-1500

|

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!